- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

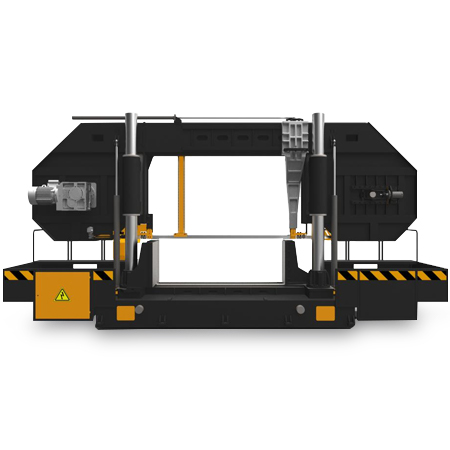

Semi-automatic twin column industrial horizontal bandsaw for general production cutting of all types of steel and non-ferrous metals. Suitable for cutting round, square and rectangular materials.

Cutting capacities and machine specification:

| TECHNICAL SPECIFICATIONS | KSY 1600 x 2500 |

| Capacity 90° (mm) – Round | Ø 1600 |

| Capacity 90° (mm) – Square | 1600 x 1600 |

| Capacity 90° (mm) – Rectangle | 1600 x 2500 |

| Main Motor | 11 kW |

| Coolant Motor | 0,55 kW |

| Hydraulic Motor | 4 kW |

| Conveyor Motor | 0,18 kW |

| Blade Size | 16550 x 80 x 1,6 |

| Coolant Tank Capacity | 230 ltr |

| Hydraulic Tank Capacity | 60 ltr |

| Feeding Height | 675 mm |

| Height-Width-Length | 4000x2000x8400 mm |

| Weight | 19000 kg |