- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

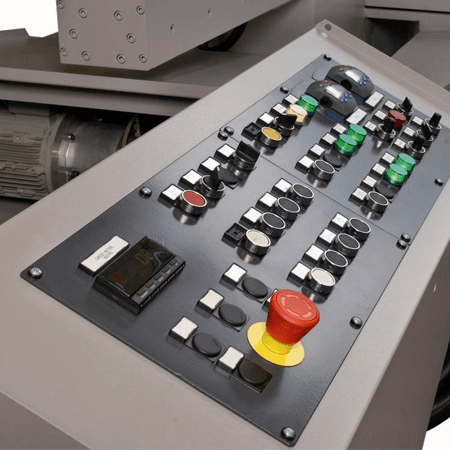

Semi-automatic twin pillar bandsaw for cutting large solid materials in a demanding production environment.

| Cutting capacity at 0° | Round: 900mm Square: 900mm Rectangular: 900x900mm |

| Blade motor | 11KW |

| Blade speed | Da 14 a 60 m/min |

| Blade size | 9300x67mm |

| Blade tension | 3000kg/cm2 |

| Canted blade | 0° |

| Hydraulic unit motor power | 3KW |

| Hydraulic unit tank capacity | 80l |

| Coolant tank capacity | 220l |

| Weight | 8450kg |

| Size | 4485x1680x3150mm |

| Working table height | 790mm |