- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

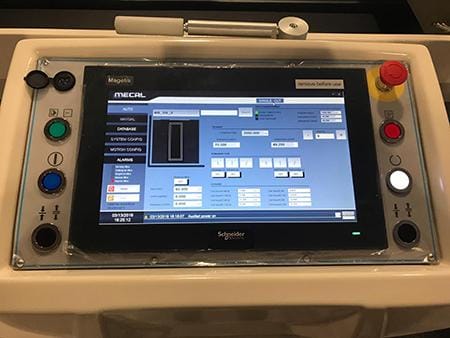

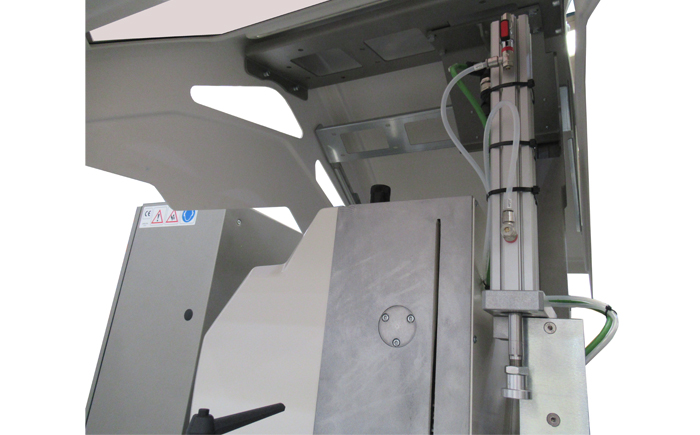

New Standard features – Brand new design – Magelis 10″ touch screen HMI – LED machine status strips – Electronic section height detector – Pneumatic pop-up centre support

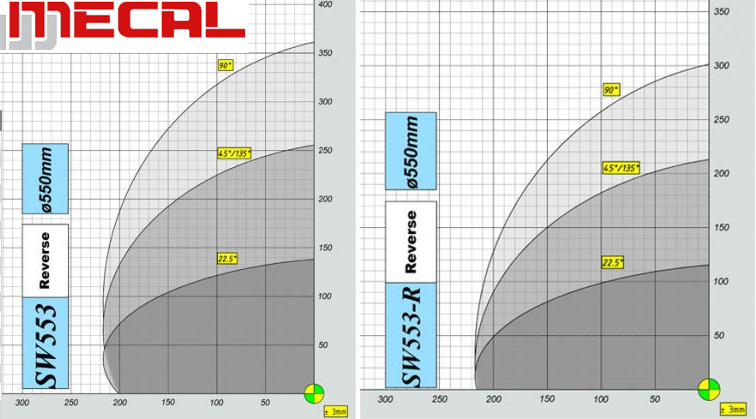

Double mitre saw with pneumatic positioned outward tilting heads with a range of +90°to -22.5° and intermediate angles set on large sector plate. The Windows embedded PC control system with Magelis 10″ colour touch screen HMI is simple to use for either quick processing of random cuts, or from pre-programmed cutting lists. The system allows the composition of complicated frame styles. The PC has the ability to receive cutting lists from compatible external software via the LAN or USB, and print labels containing job data or bar codes for integration with CNC machining centres. The R version has an extended width of cut with slightly less height.