- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

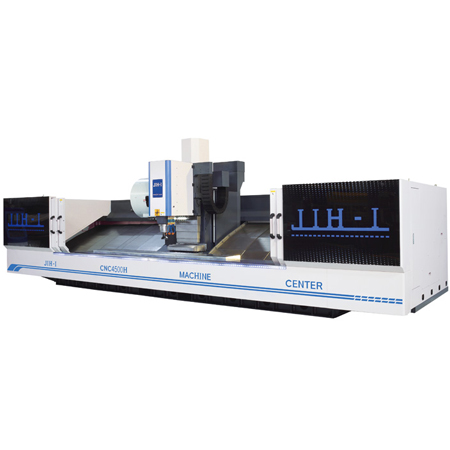

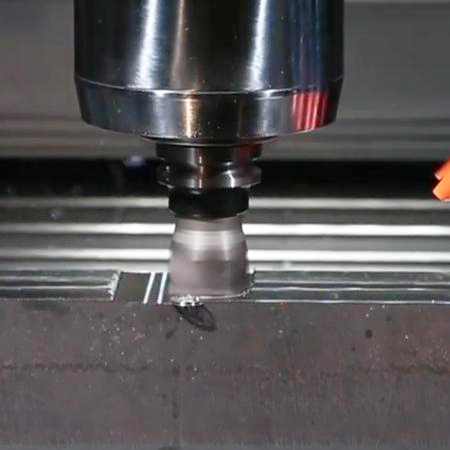

Heavy duty 3 axis CNC for machining steel and heavy aluminium profiles and solids. The machine has the ability to work long lengths and single or multiple small pieces.

JIH6500-H | |

Stroke | Technical |

| X Axis Stroke | Standard 6500mm (optional 4500mm x 5500mm) |

| Y Axis Stroke | Standard 510mm (optional 650mm) |

| Distance from Spindle Nose to Table | Min 160mm to max 670mm |

Table | |

| Table Design | 5 Tee slot 94mm centres |

| Table Width | 450mm |

| Max Load | 1000kg |

Spindle | |

| Speed | 8000 rpm (optional 10-12000 rpm) |

| Motor Power | 11kw 15hp |

| Spindle Taper | BT40 (Opt. BT50 / 6000 rpm) |

Feed Speeds | |

| X Axis | 40 m/min with rack feed (Opt. ball screw 24 m/min) |

| Y Axis | 24 m/min with ball screw |

| Servo Motors (X – Y – Z) | 5kw – 3.5kw – .5kw (Mitsubishi) |

General | |

| Magazine Capacity | 24 tools |

| ATC Type | Arm Type |

| Tool Holder | BT40 |

| Pull Stud | 45° |

| Max Tool Length | 100mm |

| Max Tool Weight | 7kg |

| Machine Weight | (6500mm) 21000kg |

| Machine Dimensions | 1200 x 3100 x 3100 mm |