Imet XT4 Enclosed Band Saw

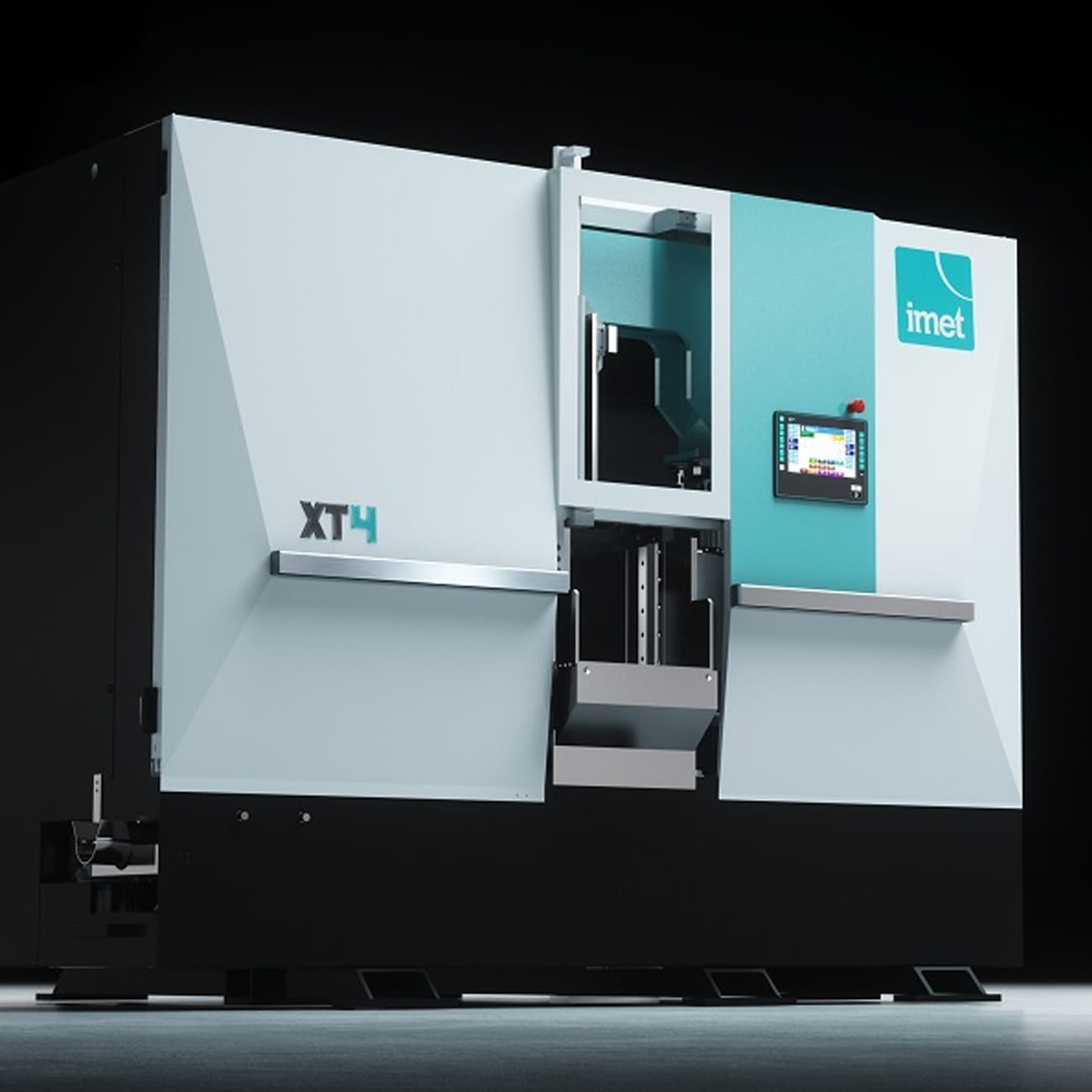

The XT4 is born from years of in-depth research which has ultimately lead to the development of a highly compact unit with no compromise on quality. This sleek, innovative machine has been designed with operator safety being of paramount importance, so at first glance it can appear to be a completely inaccessible. However, on closer inspection of the XT4, the operator is able to access all areas very quickly via specially developed opening systems on either side of the machine.

Machine Features

- Clamping vices move at the same time to ensure optimum clamping of the material. Also bars which are not completely straight can advance through the system without issue and all vice pressures are adjustable. This system also allows the vices to ‘back off’ to avoid the blade rubbing on the cut surface during the ascent of the saw frame for the next cut.

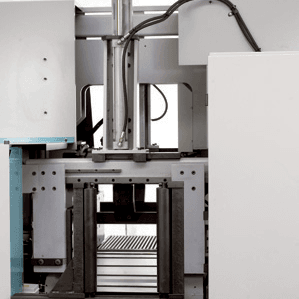

- High performance TCT bandsaw blades are suitable for this machine and it features hydraulically pressured TCT blade guides for maximum precision and squareness of cut.

- Lateral roller bearings take the blade twist load prior to entry into these guides and are adjustable. The moving guides are automatically positioned close to the cutting area, again, for maximum precision.

- Options for Short Batch & One-Off Sawing there is the possibility to cut not completely the material section in in automatic cycle.

- Hydraulic unit equipped with a variable-capacity pump.

- The sawblade is tensioned by a hydraulic cylinder controlled by the machine software.

- Automatic Trim Cut option, if the material has an acceptable pre-sawn face, it will be accurately & automatically located relative to the blade ‘zero’ position.

- This feature saves time and cuts down on material wastage. Each time the blade is changed, the machine automatically performs a run-in procedure, reducing the cutting descent speed by up to 30%,for a set time recommended by the blade manufacturer.

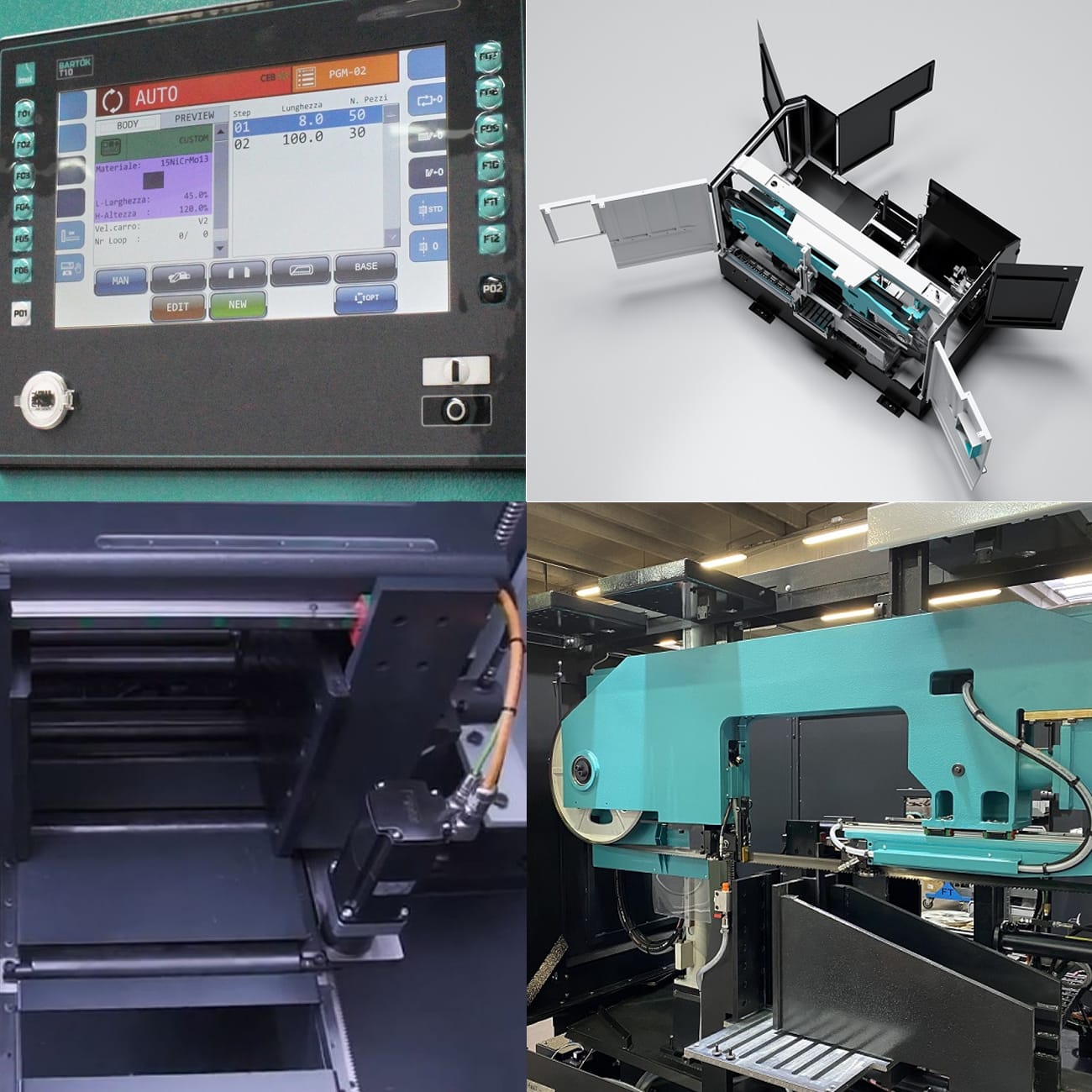

- The software allows to memorize up to 99 cutting programs with different cutting lengths and quantity’s, these programs can be personalised and easily used.

- Blade thickness is automatically detected as well as the automatic feeder stroke.

- The material length needed to complete the cutting program is displayed when the material sizes and quantities have been programmed. All operating functions of the machine, errors and problem solving messages are clearly displayed.

- A device for checking the accuracy/ squareness of the cut, with automatic adjustment or stopping of the saw frame descent speed in the event of blade deviation.

- Machine feeder electrically driven with recirculating-ball screw controlled by a sensor; automatic reset; the weight of the bar is supported by the roller table and not by the feeder, assuring a higher precision with the passing of time and lesser wearing down of the moving parts.

| Cutting area | 90° |

| Cutting capacity at 90° | Round: 360mm Squared: 360mm Rectangular: 360x360mm |

| Capacity with bundle cutting | 350x350mm 90x10mm (scrap-end with bundle: 210mm) |

| Minimum scrap-end | 60mm (available in option 30mm) |

| Minimum cutting diameter | 20mm |

| Blade size | 5900x41x1.3mm |

| Blade inclination | 0° |

| Blade motor power | 5.5KW |

| Blade speed | 15÷150 m/min |

| Sawframe motor reducer | Brushless 1/9 6Nm low backlash planetary |

| Feeder motor reducer | Brushless 1/25 6Nm low backlash planetary |

| Feeder length | 500 mm |

| Hydraulic unit power | 2.2KW |

| Hydraulic unit tank capacity | 60l |

| Collant tank capacity | 100l |

| Weight | 3500kg |

| Machine size . | 2800x1777x2200mm |

| Minimun cutting lenght | 10 mm |

| Working table height | 870mm |

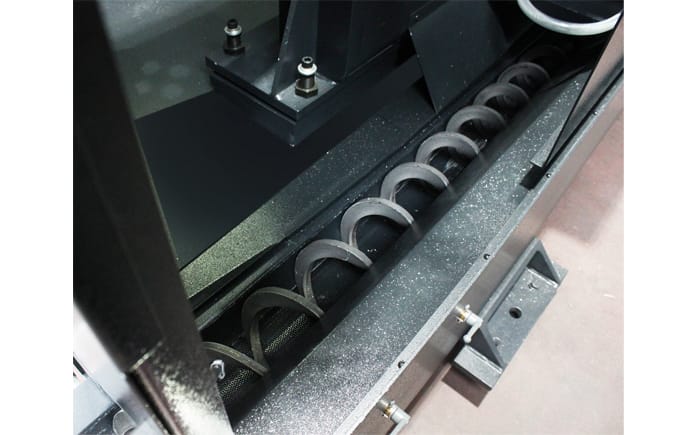

| Chips conveyor height | 420mm |

Reviews

There are no reviews yet.