SKALAR X3000 bandsaw blade

The high-performer for high-strength materials

For manufacturers working with high-strength steels, tool steels, or special alloys, the SKALAR X3000 is the blade built to keep up. Developed exclusively by WIKUS, this next-generation bimetal band saw blade features a re-engineered tooth tip material that delivers significantly higher hardness and wear resistance than traditional M42 blades — without compromising on toughness.

Paired with a carrier band made from high-grade alloyed tempering steel, the X3000® ensures reliable performance in continuous operation. The result? Longer blade life, faster cuts, and reduced machine downtime — even in the most demanding cutting environments.

If you’re pushing the limits of material and machine, the SKALAR® X3000® is the blade that won’t hold you back.

Cutting standard metal materials? Take a look at the base product, SKALAR M42

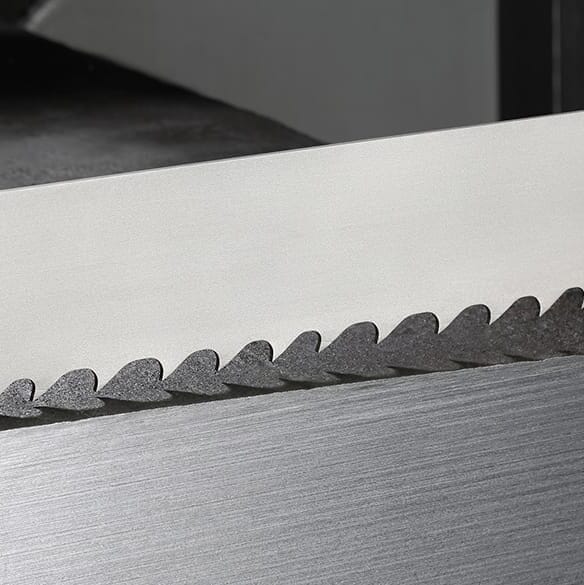

Bandsaw Blade Structure

As with all SKALAR® band saw blades, the high cutting performance of the SKALAR X3000 bandsaw blade is based not only on the special properties of the cutting material, but also on the specially adjusted tooth geometry, a slightly increased positive rake angle and the optimum setting sequence

In addition, an increase in stability in the backing material supports high blade-life, especially when sawing difficult-to-machine, high-alloy materials such as quenched and tempered, annealed, carbon steels with tensile strengths greater than 1000N/mm².

Materials

| Application

|

Advantages

| Features

|

Manufacturer Info

Find out more about Wikus: Why Wikus

Reviews

There are no reviews yet.