Mecal Label Printer

Thermal label printer for producing bar codes when integrating with a cnc machining centre, or recording job/customer data to attach to the workpiece.

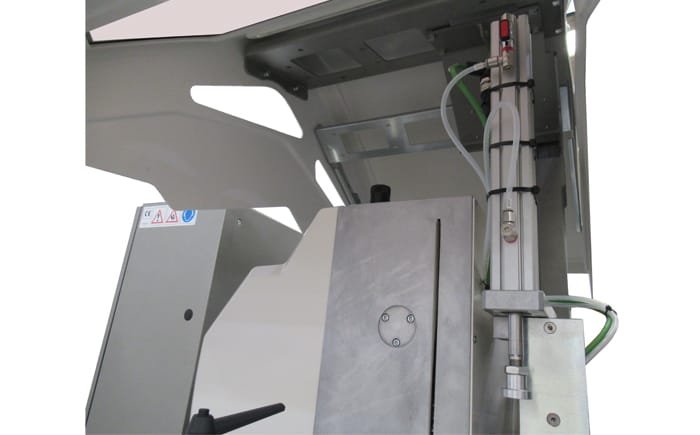

Addimist

Pure oil micro-mist blade lubrication system recommended over the standard soluble system, as it delivers a high performance neat oil in minute highly controlled doses. Giving a cleaner working environment with no odours or risk of skin irritation sometimes connected with soluble fluids. Each dose cane be scalled by adjusting the size of each pulse and the frequency of each pulse.

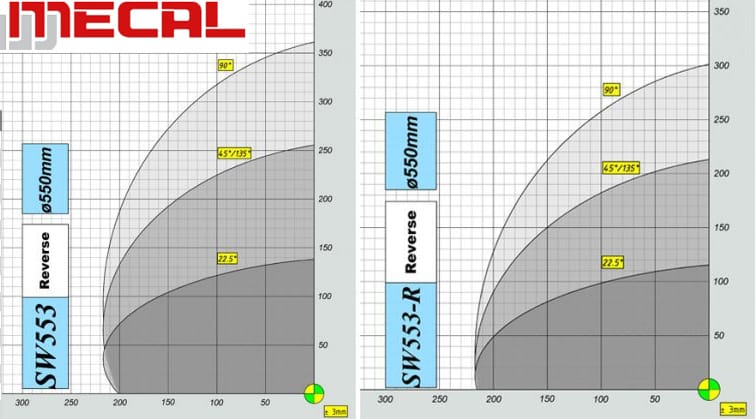

EW-3 Extractor

Complete swarf extraction system taking from both sawblade chambers, fully compliant to handle aluminium, pvc, brass, wood, copper and composite materials. The steel container is removable for easy emptying, and the filter bags are maintained with either the standard manual shake lever or the optional pneumatic shake.

Sound Insulation

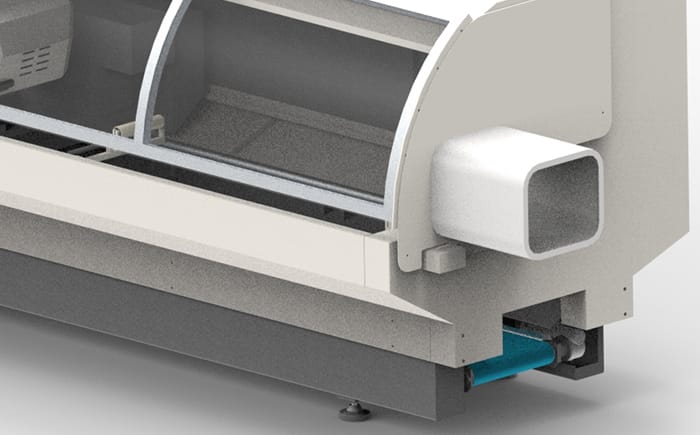

Available as SW555 version factory order with full sound reducing cabinet and automatic loading doors. It is not possible to have vacuum swarf extraction. The standard machine has a central collection trough with open ends to sweep out the swarf, or the optional belt conveyor can be fitted.

Belt Conveyor

Available for all versions, but more suited to the SW555 version with enclosed cabinet.

Reviews

There are no reviews yet.