Mist Extraction System

Virtually Mandatory now mist extraction is an important option to consider either supplied with a new machine or easy retro-fit. Our Italy Vacuum is the most efficient and cost effective solution. Lower purchase cost than leading brand, no scheduled servicing costs as all filters with the exception of the HEPA filter can be user cleaned with an air gun or just warm water, and finally the extraction performance is industry leading by comparison.

Clamping options

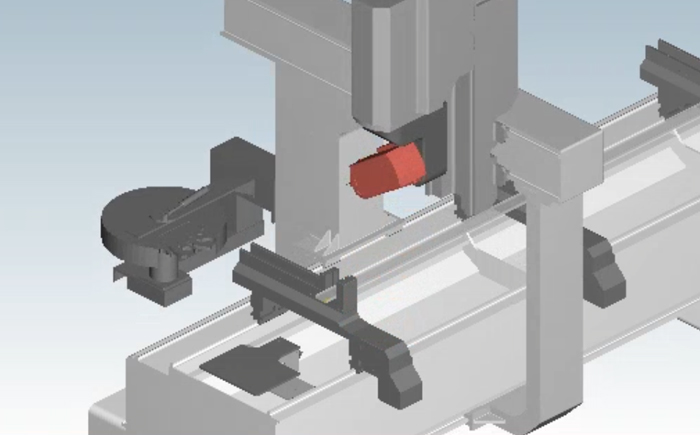

MMI-this choice has each clamp motorised to move individually to position. MDT-this choice has each clamp motorised in a different way, they are more powerful and now each clamp is an additional axis. For example you can have 4 programs for individual components (eg parts for a window sash) the process will saw each piece to length, mitred if required then separate the elements to allow machining of 3 sides and ends if required. Both versions have 8 clamps as standard, additional items can be added to suit application.

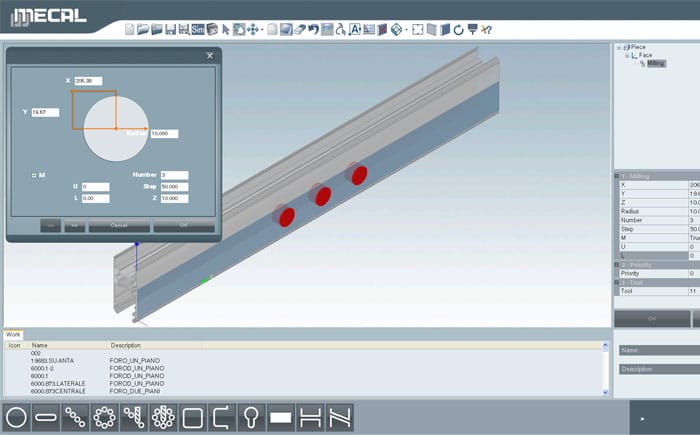

Simulator Software

Job simulator software which shows an accurate simulation of the actual job in real time very graphically. Indicating timings and potential process errors.

Belt Conveyor

A rubberised belt conveyor to transport captured swarf and offcut pieces to the end of the machine where a collection container can be placed.

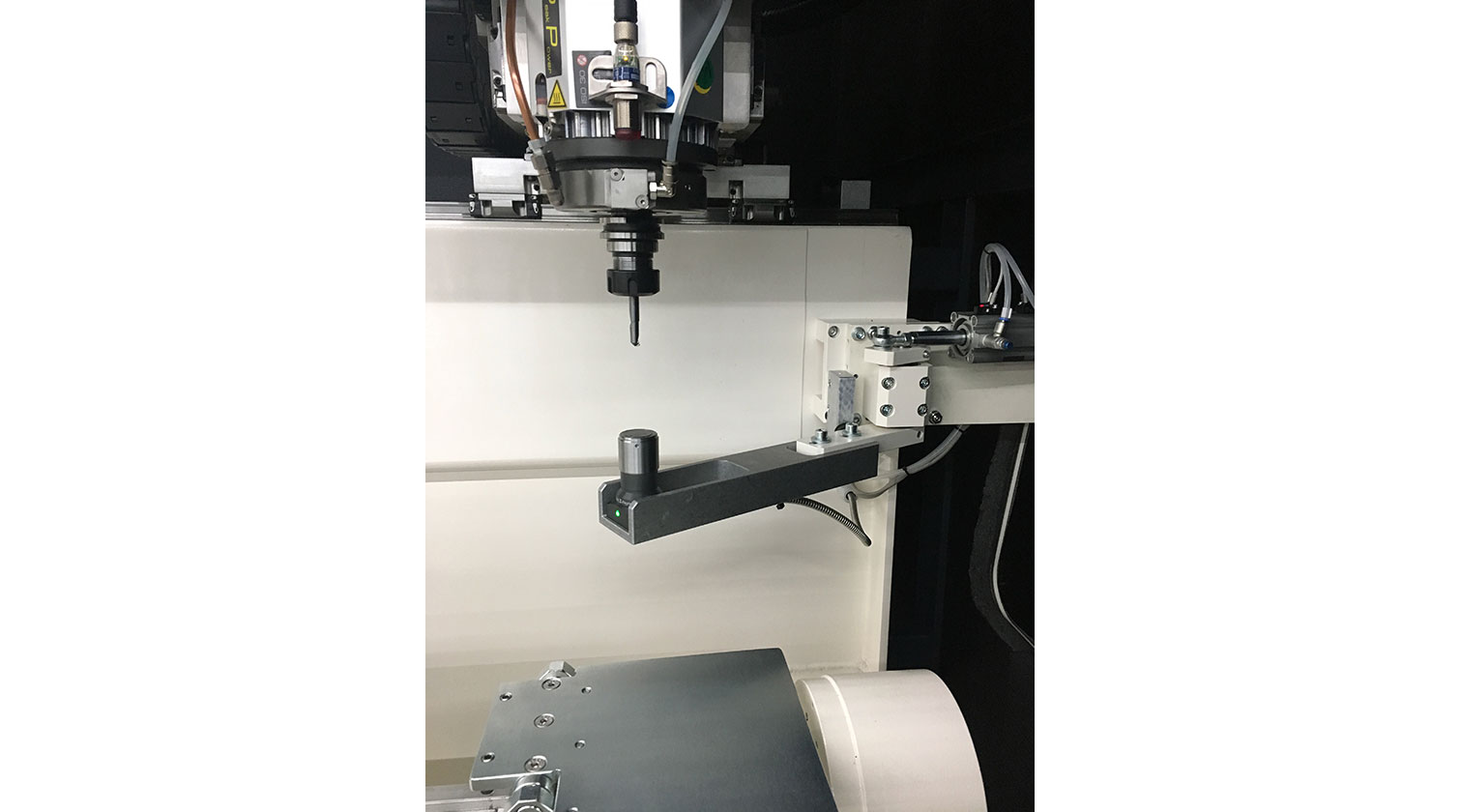

Tool Presetting Probe

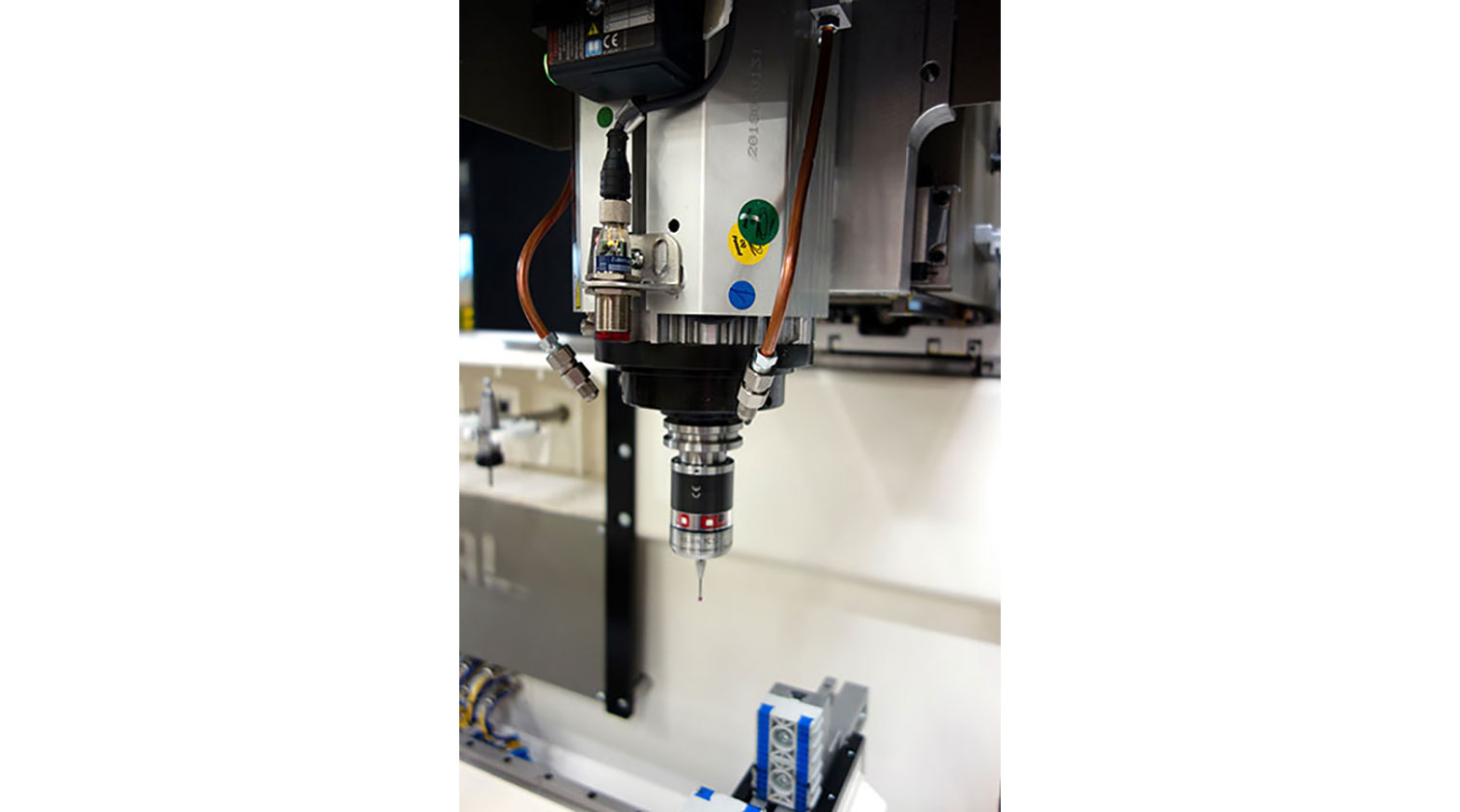

Tool Pre-setting Probe

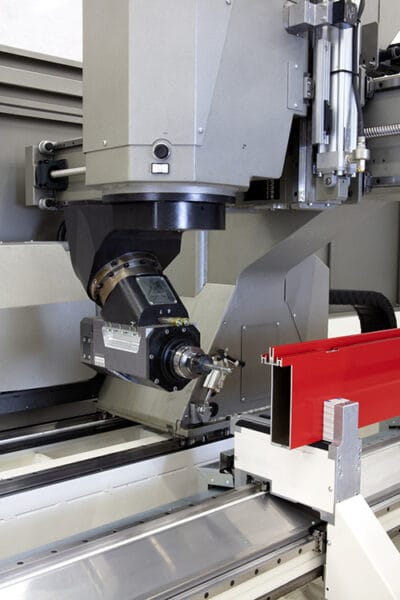

Multidirectional Probe

Multi directional probe with detection based on Z axis orientation

Barcode reader

For receiving job data when integrated with a double mitre saw that has the thermal label printer. The job data is usually provided by external software.