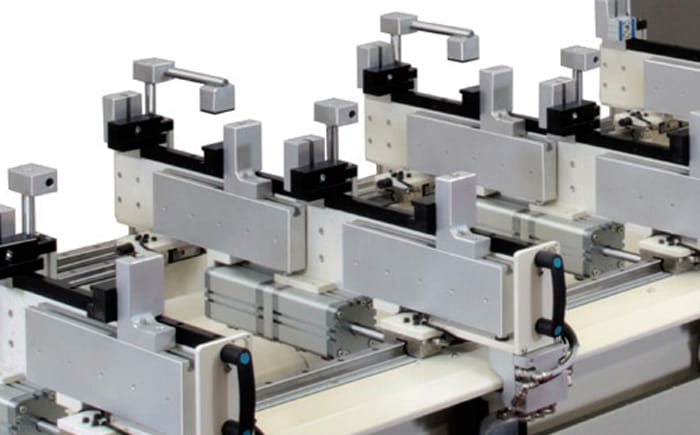

Clamping Positioning

DPM-where the clamps are sequentially positioned by the spindle carriage.

MMI-this choice has each clamp motorised to move individually to position.

Both versions have 8 clamps as standard, additional items can be added to suit application.

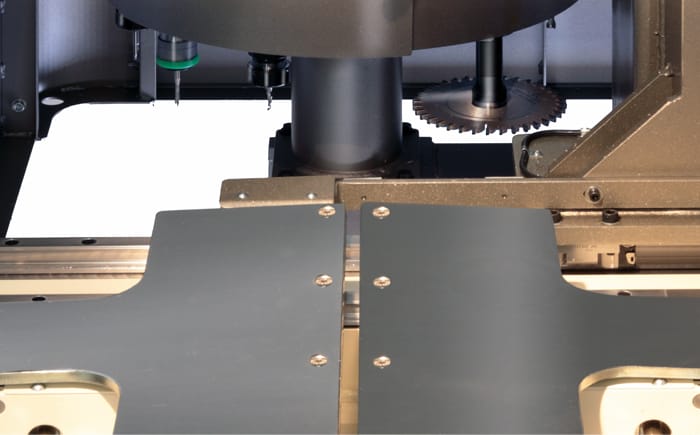

Clamp Option

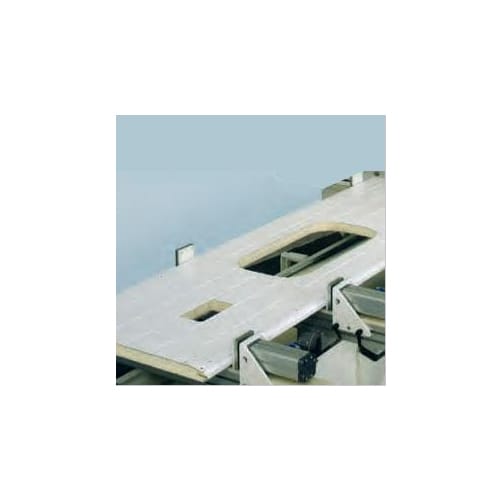

To increase loading capacity of suitable dimension pieces we have a unique double clamping factory option.

Centre Stops

The optional pneumatic centre stops combine with the standard end stops to allow loading of 4 pieces.

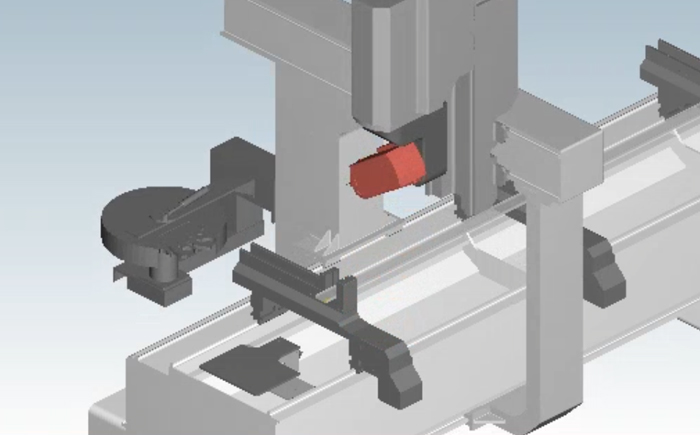

Angle Drives

Angle drive with 2 tools can be orientated in either Y axis or Z axis direction, the required direction must be specified on ordering.

Angle drive with sawblade can be orientated in either Y axis or Z axis direction, the required direction must be specified on ordering.

Optional additional magazine may be required for auto change of the unit. The tools within the angle drive have to be manually changed.

Additional Magazine

Commonly used to mount the angle drive heads.

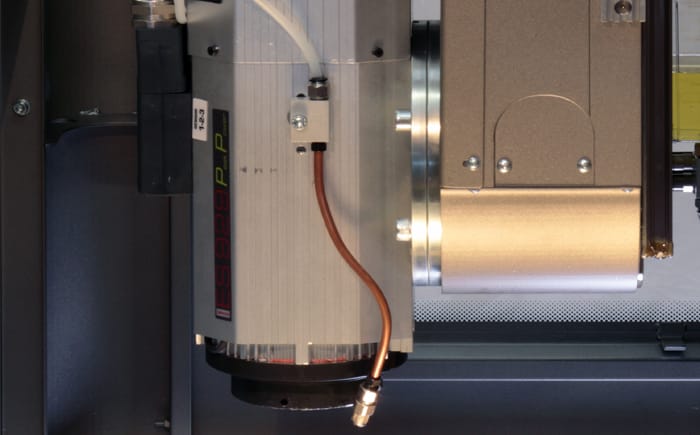

Spindle Upgrades

7.5kw air cooled with axial encoder to facilitate rigid tapping functions.

10kw liquid cooled with axial encoder to facilitate rigid tapping functions.

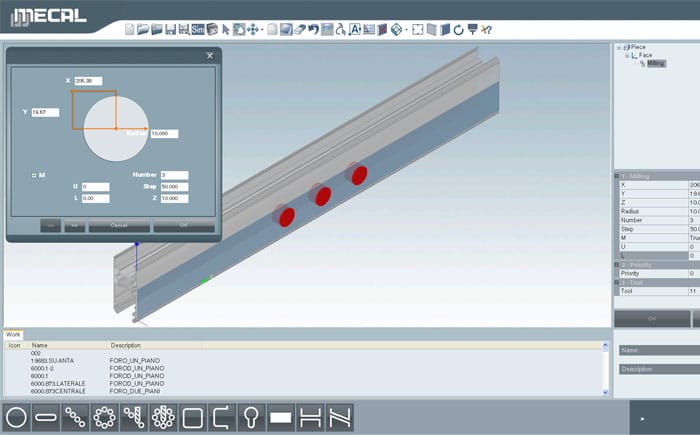

Simulator

Job simulator software which shows an accurate simulation of the actual job in real time very graphically. Indicating timings and potential process errors.

Belt Conveyor

A rubberised belt conveyor to transport captured swarf and offcut pieces to the end of the machine where a collection container can be placed.

Swarf Drawers

Set mobile of steel swarf collection drawers

Other Options

Automatic length measuring device

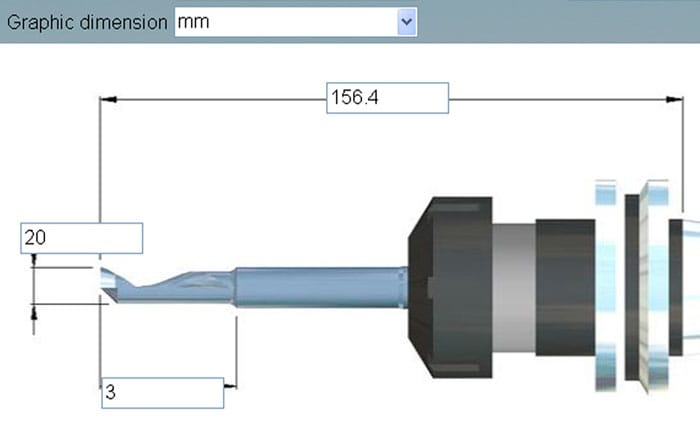

Multi directional probe with detection based on Z axis orientation

Automatic length measuring device

Multi directional probe with detection based on Z axis orientation

Bar Code Reader

For receiving job data when integrated with a double mitre saw that has the thermal label printer. The job data is usually provided by external software.

Reviews

There are no reviews yet.