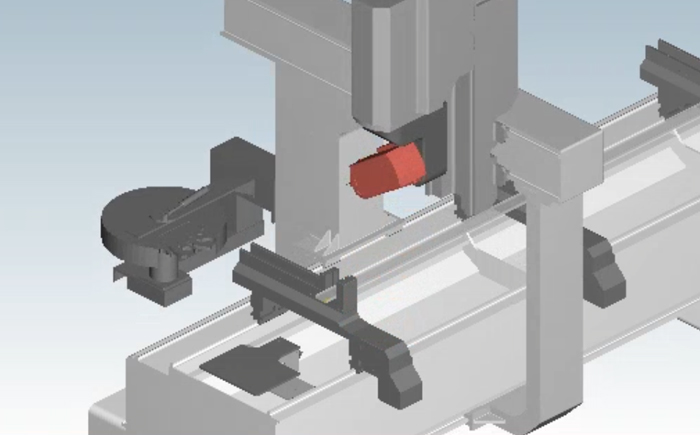

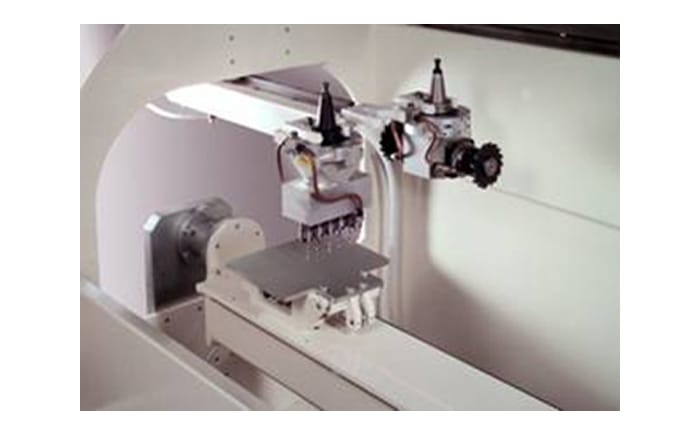

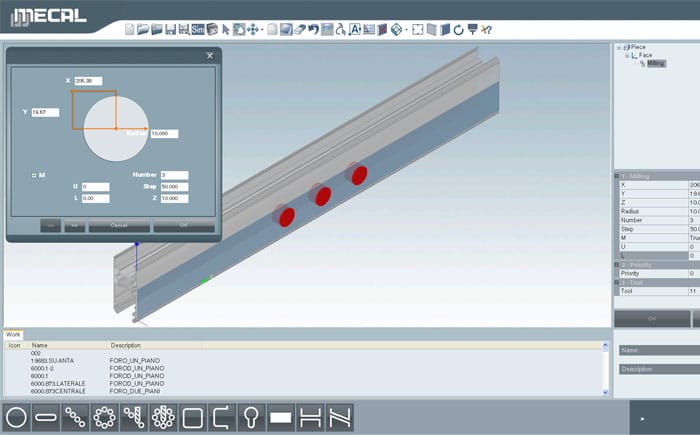

Mecal Kosmos TF 3 Axis Machining Center

For high speed machining of aluminium, steel, brass, copper and PVC materials. The Kosmos can be used in numerous applications including; windows, doors and curtain walling, automotive, aerospace, engineering, internal partitions, sign manufacturing, air conditioning and refrigeration. We have successfully installed these machines for a very diverse range of applications including; machining slots, pockets, holes and custom shapes, tapping, rigged tapping, drilling and flow drilling, end slots.

| X axis stroke | mm | 4225 |

| Positioning speed X-axis | m/1’ | 80 |

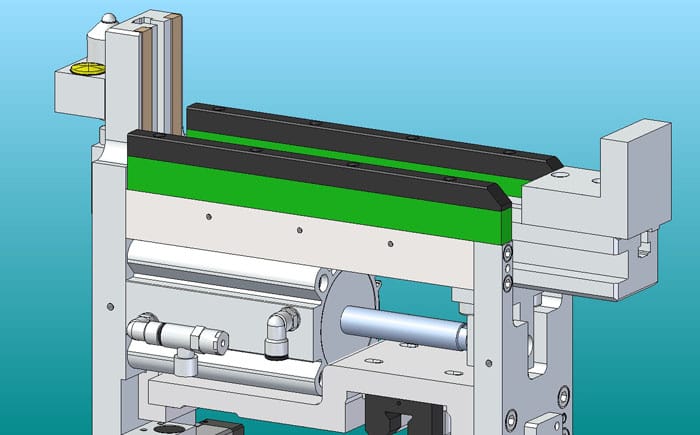

| Y axis stroke | mm | 530 |

| Positioning speed Y-axis | m/1’ | 30 |

| Z axis stroke | mm | 410 |

| Positioning speed Z-axis | m/1’ | 30 |

| A axis stroke | deg | ± 125° |

| Electrospindle rated power | kW | 6.0 |

| Cooling system | Air | |

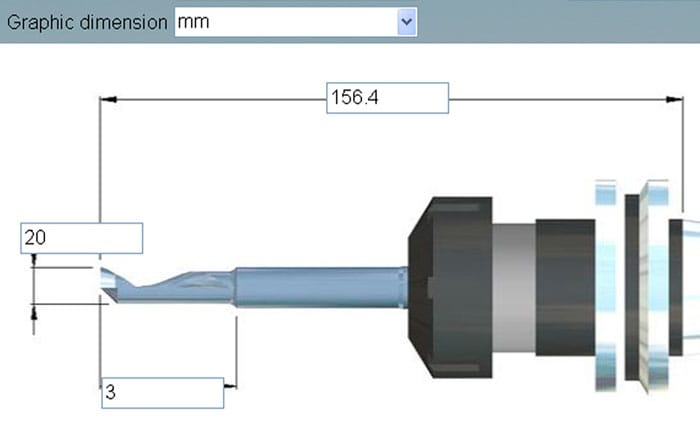

| Tool holder cone | ISO30 | |

| Max rotation speed | rpm | 18000 |

| Weight | kg | ± 3200 |

Subject to technical changes

Reviews

There are no reviews yet.