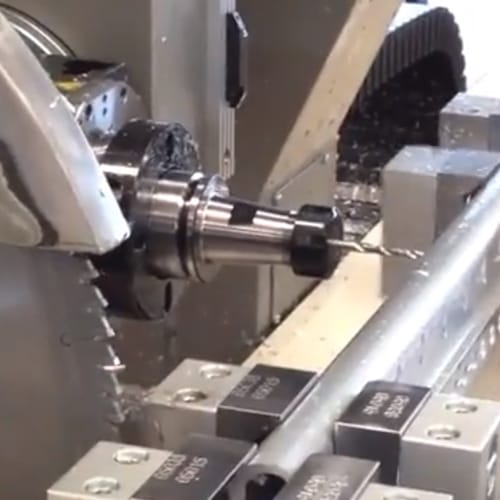

Mecal FMM 311 Sawing and Machining Line

Ideal for producing short components

5 axis CNC

Boring, drilling, slotting, tapping and sawing

Fully automatic process

Large touch screen HMI for machine operation

Advanced CAD/CAM software

Ability to link to selected external software

Ability to use cutting and milling units independently

Optional X axis boring heads

Mecal FMM 311

Automated sawing and machining line for completing components from stock material, conceived for manufacturing short components requiring boring, drilling, slotting, tapping and cutting to length. This machining centre is ideal for producers of brackets / hinges / curtain wall fixing system / office partition brackets / automotive components etc.

Equipped with a 500mm (19.68″) 90° saw and 4 Axis machining head, hydraulic and motorized clamps.

The illustrated version shows 2 optional X axis boring units which in this case apply a preparation to the centre bore of the extrusion. We are able to study the clients requirements and working around the flexible base machine concept add process changes and devices to facilitate a wide range of requirements.

Reviews

There are no reviews yet.