- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

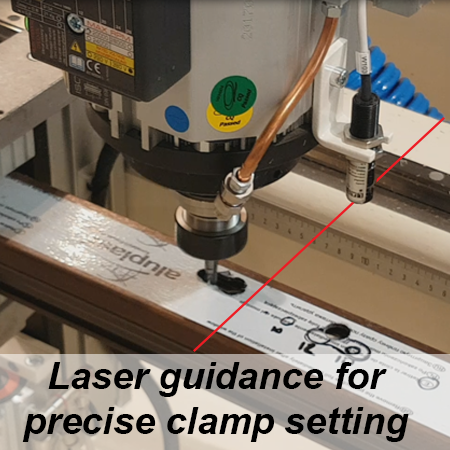

For high speed machining of aluminium and PVC materials.

Super-compact CNC machining centre, the smallest offered by Mecal. This small but mighty machine is used in numerous applications such as windows and doors including: Bi-fold ranges, curtain walling, automotive, aerospace, engineering, internal partitions, sign manufacturing, air conditioning, and refrigeration.

We have installed these machines for very diverse applications including; machining slots, pockets, holes, custom shapes, end slotting and profiling, tapping, and drilling.

Find all the information you need on the Aydo’s Axis stroke measurements and speed.

Subject to technical changes