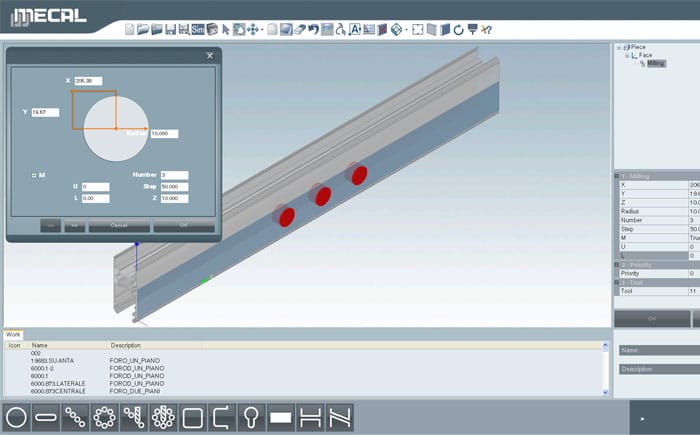

Mecal Mc 309 Nike 4 Axis Machining Center

Upgraded to full 4 axis from 3+1 at no additional cost

For high speed machining of aluminium – Steel – Brass – Copper and PVC materials. Used in numerous applications including;

|

|

|

|

|

|

|

|

|

|

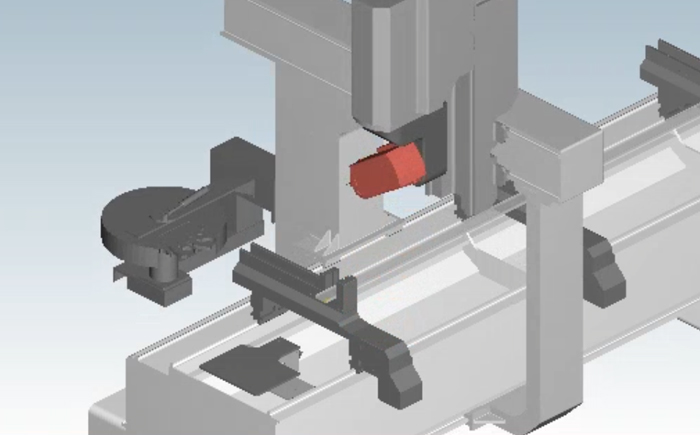

We have installed these machines for many different uses. They can machine slots, pockets, holes, and custom shapes. They also handle end slotting, profiling, tapping, rigid tapping, drilling, and flow drilling.

Machine Specification

| X-axis stroke | 3500 mm |

| Positioning speed X-axis | 70 mmm/1’ |

| Y-axis stroke | 370 mm |

| Positioning speed Y-axis | 30 m/1’ |

| Z-axis stroke | 348 mm |

| Positioning speed Z-axis | |

| A axis stroke | ± 90° |

| Electro spindle rated power | 3,8 kW |

| Cooling system | Air |

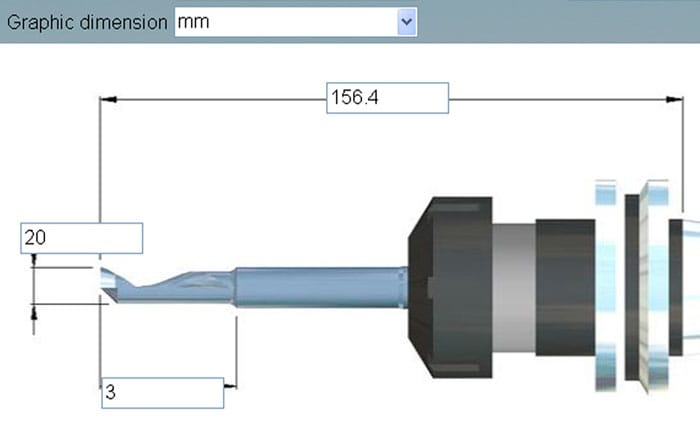

| Tool holder cone | ISO30 |

| Max rotation speed | 18000 rpm |

| Weight | ± 2200 kg |

Subject to technical changes.

Reviews

There are no reviews yet.