Contactless antistatic system

for grounding residual currents

Remote start on/off

allows the aspirator and the machinery to be switched on and off simultaneously and automatically

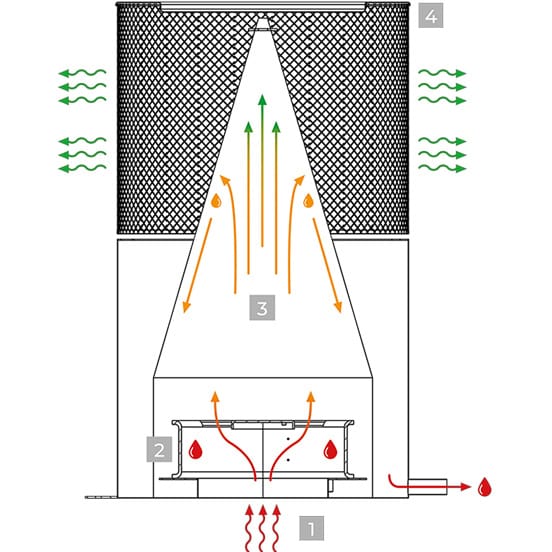

Electrostatic filters

They can represent an additional stage of filtration and are normally dedicated to the capture of oils, grease, and oily vapors. They are particularly suited and efficient when operating on air flows at low scroll speeds.

Standard support for the Tecnomist model

Comprised of a sturdy tubular structure in a “C” shape, it allows the placement of the extractor at the top of the machine tool.

Telescopic Support

Specially designed to support extraction pipes for CNC machines, it allows the pipe to descend from the top, avoiding any kind of obstruction for the operator.

Circular Support

Specially designed to support the Mastermist vacuum cleaner on the top of the cnc machines on which it is normally installed, it consists of simple vertical threaded steel bars suitably welded together

Lubricating Oil Container for Recycling

A special and professional container for emulsifying oil in 18/10 stainless steel with a capacity of 30 liters and capable of resisting all aggressive agents contained in various types of lubricating oils

Custom Air Supports

Specially designed to be able to position Master Mist in the most suitable and efficient position

Reviews

There are no reviews yet.