- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

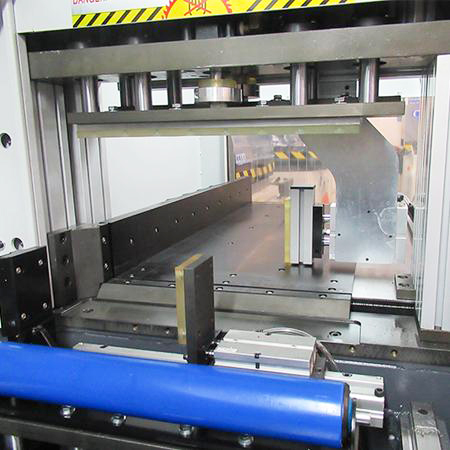

Recommended for volume production cutting of aluminium extrusions and solids, widely used in the heatsink industry. The heavy construction of this machine together with innovative design and use of highest quality components put this machine right at the top of pile, and that even before we mention the competitive price. You can easily pay double and still not match the performance and reliability this machine.

LS versions have servo ball screw feed of the sawblade, which allows variable feed rates to be programmed to optimise cutting times of different shapes of material, and set precise cutting heights. Click here for automated loading version

Detail | NC24-L & NC24-LB |

| Servo Drive System | Ball screw (or high precision rack & pinion) |

| Maximum Feed Stroke | NC24=1000mm NC24LB=2500mm |

| Cutting Accuracy | ±0.1mm |

| Saw Spindle Speed | 1500 ~ 3500 rpm with inverter |

| Motor Power | 15hp |

| Inverter | 15hp |

| Hydraulic Feed Motor | 2hp |

| Servo Motor | 1kw (option for 1.5kw) |

| Cutting Table Height | 920mm |

| Touch Scrren HMI Size | 7″ |

| Blade Size Range | 250mm to 600mm |

| Dimensions L x W x H | 3500 x 2100 x 1860 mm |

| Weight | 2300kg |

| Cutting Capacity H x W mm | 200 x 200 – 175 x 210 – 130 x 350 – 40 x 400 |