- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

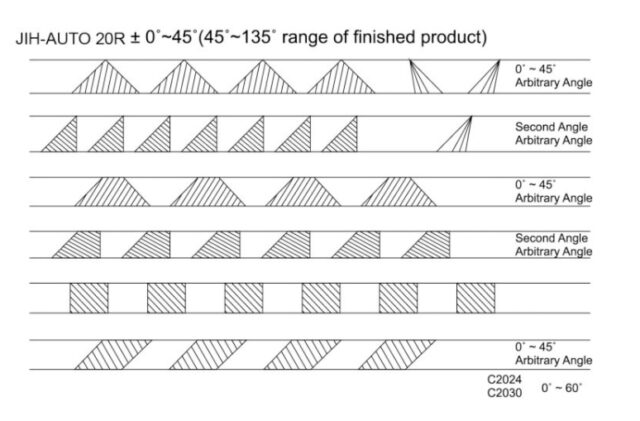

Highly productive cutting cell comprising of large 500mm blade automatic mitre saw with NC powered head rotation and servo driven material pushing system. The standard machine is manually loaded, there is an option for automatic material loading. The pushing and loading elements are available in customer definable operational lengths, standard is 6500mm. There are many options for the unloading side from simple roller table to robotic transfer.

Detail | JIH Auto 20R |

| Automatic Cutting Angle | + 45° ~ 90° ~ – 45° |

| Sawblade Dimension | 24″ (500mm) |

| Spindle Speed | 2800rpm |

| Motor Power | 7.5hp |

| Cutting Table Area | 920mm x 650mm |

| Cutting Table Height | 875mm |

| Table Rotation Servo Motor | 400w |

| Pusher Servo Motor | 750w |

| Standard Feed Lengths | 2.5m or 6.5m |

| Positioning Accuracy | ± 0.15mm |

| Pushing Force | 50kg |

| Positioning Speed | 20~50 m/min |

| PLC Job Memory Capacity | 100 |

| HMI Type | 7″ Touch Screen |

| Machine Weight 2.5m/6.5m | 1100kg/1400kg |

| Dimensions L/W/H 6.5m Version | 8400mm x 1100mm x 1850mm |