JIH-18 & 24 DB

Automatic CNC saw recommended for high volume cutting of relatively short pieces.

Specification

Model |

JIH-18D B Type |

JIH-24D B Type |

| Applicable Machine | JIH-18 D TYPE | JIH-24 D TYPE |

| Automatic Drive System | Ball screw (servo motor drive) | Ball screw (servo motor drive) |

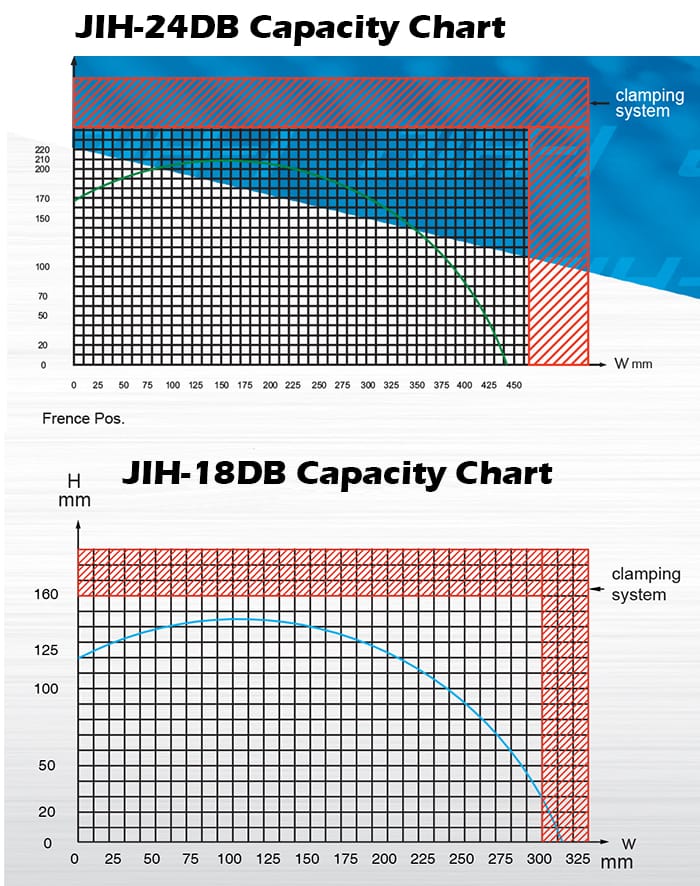

| Cutting Capacity (H x W) | 125 x 125, 100 x 200, 20 x 280 mm | 160 x 300, 50 x 420 mm |

| Max. Feed Distance (one time) | 300 mm unlimited recycle feed distance | 350 mm unlimited recycle feed distance |

| Automatic Feed Accuracy | ±0.1 mm | ±0.15 mm |

| Cutting Length Display & Set Up | By touch screen | By touch screen |

| Saw Spindle Speed | 3,200 rpm | 1,800 rpm |

| Saw Spindle Motor | 7.5 HP (10 HP opt.) | 10 HP |

| Hydraulic Feed Motor | 1 HP (Opt.) | 1 HP |

| Servomotor | 1 kW | 1 kW |

| Max. Load | 100 kgs | 100 kgs |

| Table Height From Floor | 860 mm | 830 mm |

| Touch Screen | 7″ | 7″ |

| Saw Blade Size | 18″ x 1″ bore | 24″ x 1″ bore |

| Air Pressure | 4 ~ 6 kgs / cm² | 4 ~ 6 kgs / cm² |

| Machine Dimensions (L x W x H) | 1300 x 1000 x 1800 mm | 1675 x 1337 x 1863 mm |

| Package Dimensions (L x W x H) | 1420 , 1100 x 2000 mm | 1775 x 1437 x 2063 mm |

Cutting Chart:

Reviews

There are no reviews yet.