Addimist

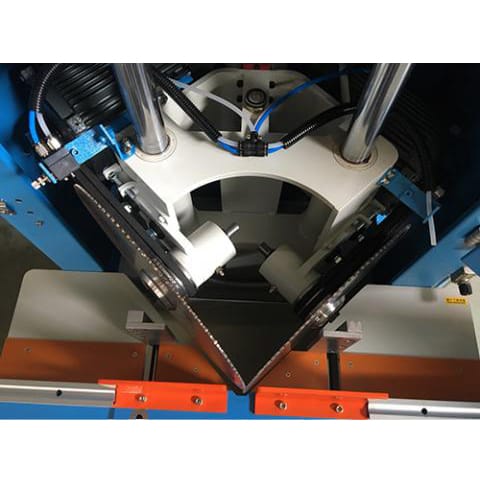

Pure oil micro-mist blade lubrication system recommended over the standard soluble system, as it delivers a high performance neat oil in minute highly controlled doses. Giving a cleaner working environment with no odours or risk of skin irritation sometimes connected with soluble fluids. Each dose cane be scaled by adjusting the size of each pulse and the frequency of each pulse.

Reviews

There are no reviews yet.