- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

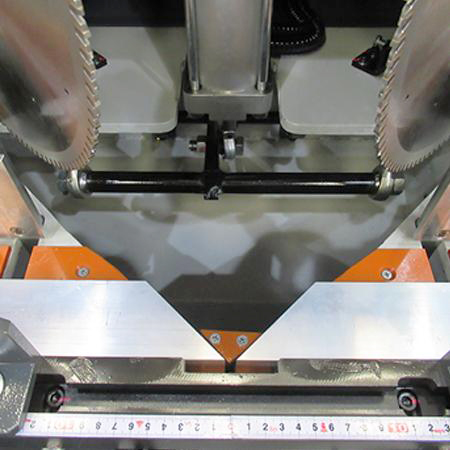

Vertical double mitre saw recommended for volume production of small double mitred extrusion components, commonly used in ventilation-window-picture frame and case manufacturing industries. Supplied standard with 3000mm infeed table and 3000mm outfeed table with manual material stop and digital display of the cutting length. Both tables are solid plastic covered to protect the material surface finish.

Detail | JIH-14 A Type | JIH-14 B Type |

| Cutting Angle | 45° | 45° |

| Capcity (H x W) mm | 100 x 100 mm or 140 x 90 mm | 150 x 130, 180 x 100, 250 x 70 mm |

| Saw Blade Sizes | 14″ x 1″ x 2 pieces | 18″ x 1″ x 2 pieces |

| Spindle Speed | 3400 rpm | 3000rpm |

| Motor | 2 hp x 2 | 3 hp x 2 |

| Clamping Way | 3 (vertical clamps & horizontal clamps) | 3 (vertical clamps & horizontal clamps) |

| Table Area | 870 x 260 mm | 870 x 290 mm |

| Table Height from floor | 830 mm | 800 mm |

| Infeed / Outfeed Conveyor Length | 2,400 mm | 2,400 mm |

| Net / Gross Weight | 310 / 410 kgs | 500 / 610 kgs |

| Air Pressure | 4-6 kgs / cm² | 4-6 kgs / cm² |

| Machine Dim. (L x W x H) | 1370 x 820 x 1310 mm | 1520 x 930 x 1440 mm |

| Packaging Dim. (L x W x H) | 1490 x 950 x 1510 mm | 1640 x 1050 x 1640 mm |