- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

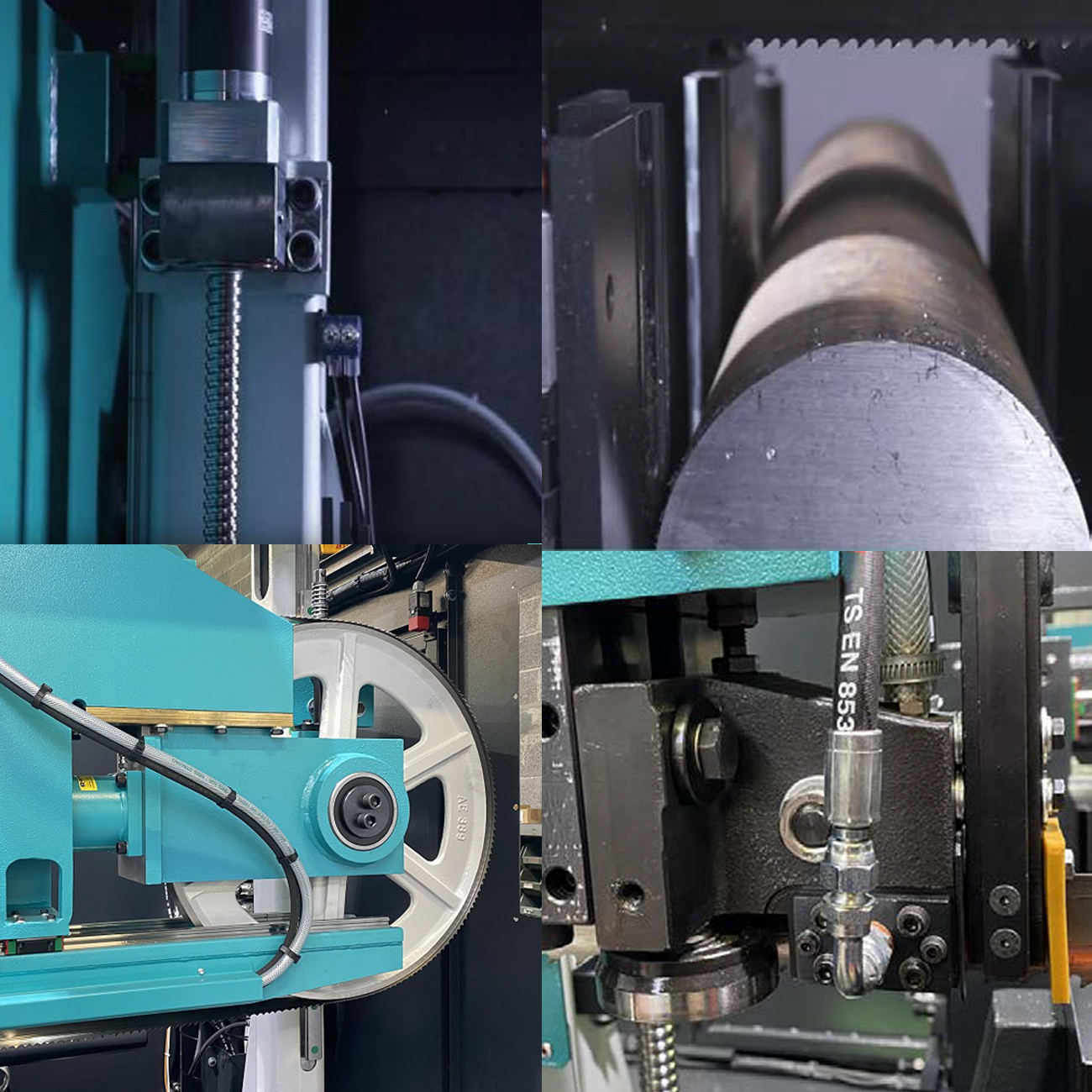

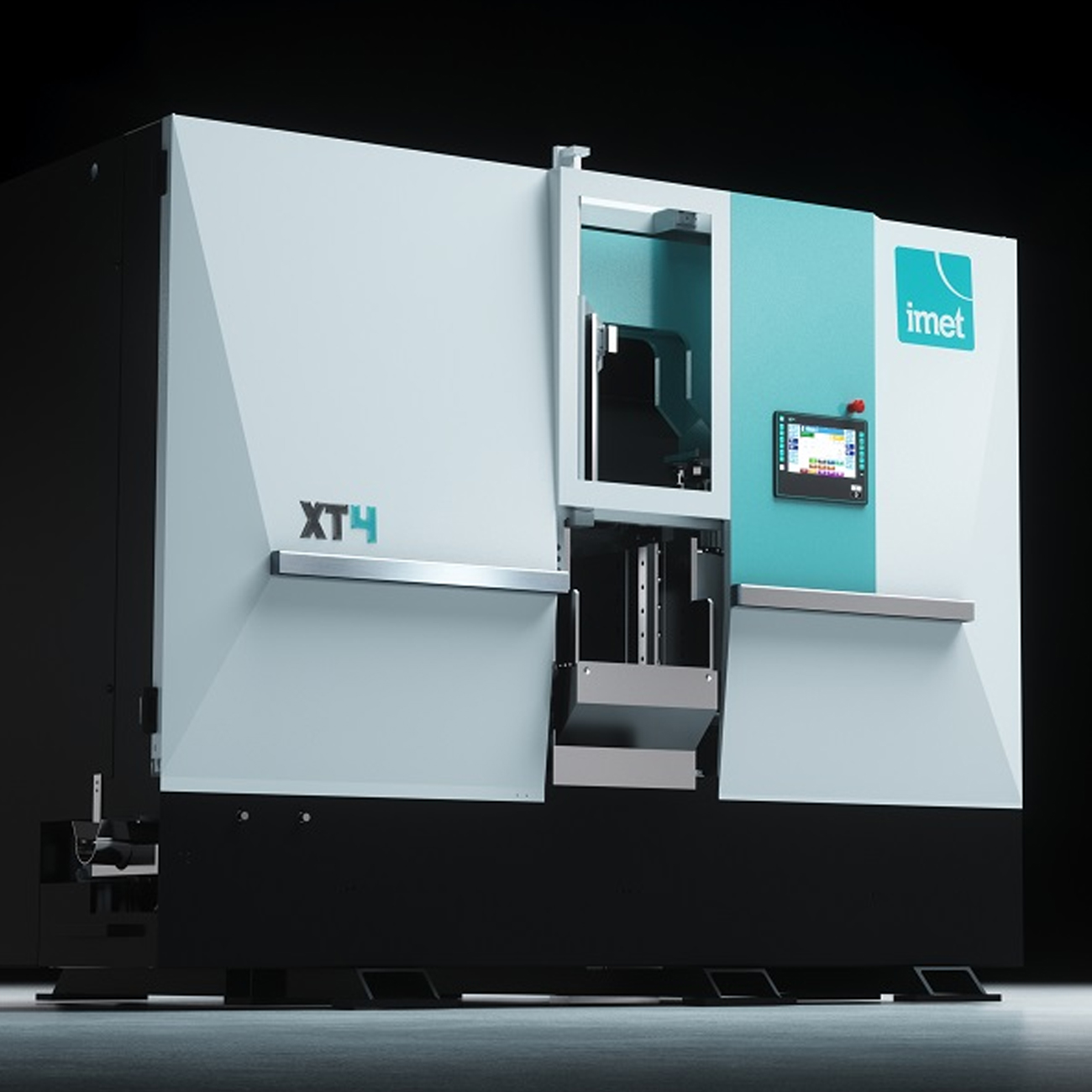

The XT range of advanced bandsaws are born from years of in-depth research. Ultimately this lead to the development of a highly compact, technologically advanced enclosed unit with no compromise on quality. This sleek, innovative machine has been designed with operator safety being of paramount importance, so at first glance it can appear to be a completely inaccessible. However, all areas of the machine are accessible through specially developed opening systems on either side of the machine.

The XT range are full of innovative features designed to enhance your metal cutting facility and lighten the operators work load through advanced automation.

For a full list of features and their benefits, download the machine data sheet from the file downloads tab on this page.

| Cutting area | 90° |

| Cutting capacity at 90° | Round: 560mm Squared: 560mm Rectangular: 520x550mm |

| Capacity with bundle cutting | 550x520mm 90x10mm Scrap-end with bundle 210mm |

| Minimum scrap-end | 60mm (available in option: 30mm) |

| Minimum cutting diameter | 20mm |

| Blade size | 7320x54x1.6mm |

| Blade inclination | 0° |

| Blade motor power | 7.5KW |

| Blade speed | 15÷150 m/min |

| Sawframe motoreducer | Brushless 1/9 6Nm low backlash planetary |

| Feeder motoreducer | Brushless 1/25 6Nm low backlash planetary |

| Feeder length | 500 mm |

| Hydraulic unit power | 3KW |

| Hydraulic unit tank capacity | 80l |

| Collant tank capacity | 160l |

| Weight | 5300kg |

| Machine size | 3600x1900x2500mm |

| Minimun cutting lenght | 10 mm |

| Working table height | 870mm |

| Chips conveyor height | 420mm |