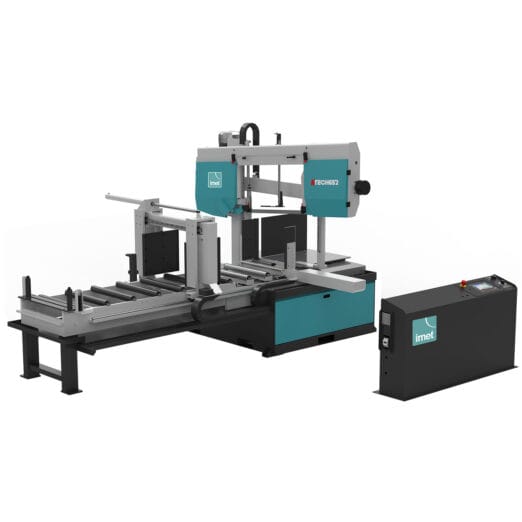

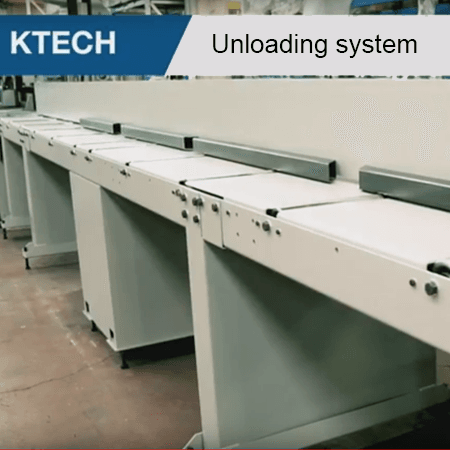

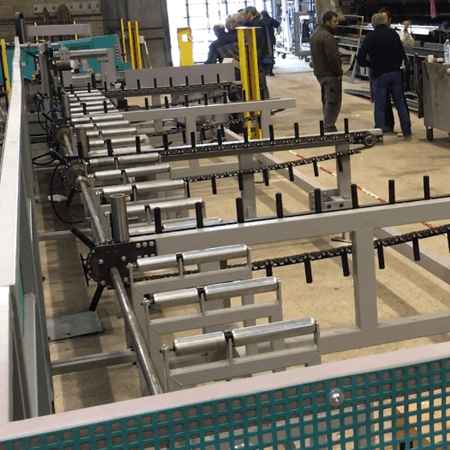

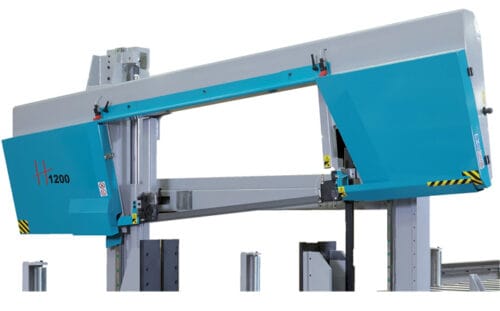

Imet Ktech 652 F2000 with Auto-loading & unloading

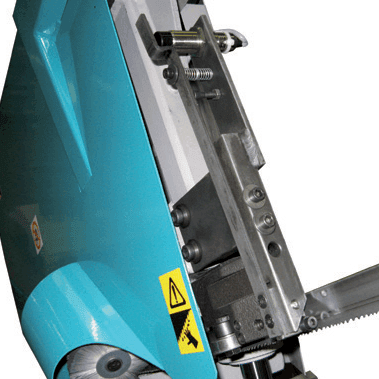

Automated twin column band saw is a complete cutting center. It is designed for automated production of mitred and straight cut pieces. This saw is perfect for making frames, fencing elements, commercial vehicle parts, and general production.

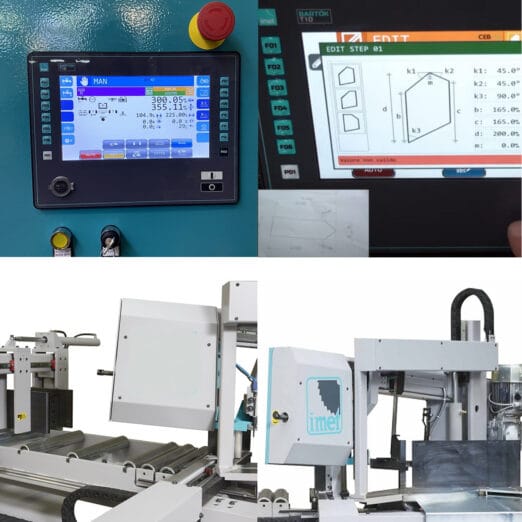

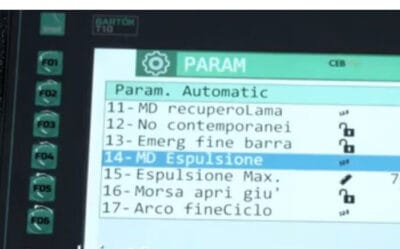

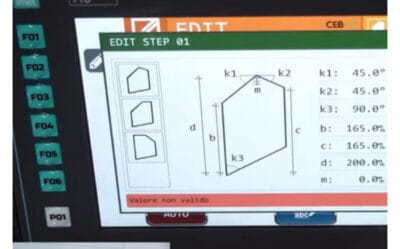

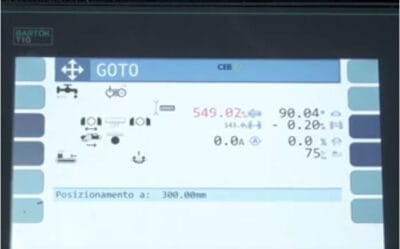

All cutting data is entered into the easy-to-use color touch screen HMI. This screen can store 300 programs for different cutting angles, piece quantities, and cut lengths.

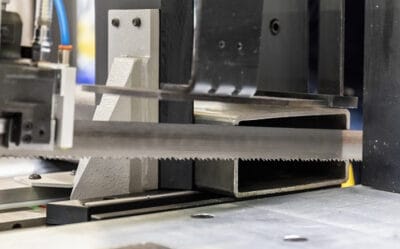

The sawblade is uniquely inclined at the end of the cut. This is ideal when cutting square sectional material and flat plate. This feature is important because it helps cut times. It also increases blade life and the use of each tooth pitch. Additionally, it reduces the load on the machine parts. This feature is also standard on the BS350/400 models. Additionally, this machine benefits from fully hydraulic vices.

| Cutting capacity at 90° | Round: 510mm Square: 480mm Rectangular: 650x450mm |

| Cutting capacity at 45° (left) | Round: 440mm Square: 430mm Rectangular: 430x430mm |

| Cutting capacity at 45° (right) | Round: 440mm Square: 440mm Rectangular: 440x440mm |

| Cutting capacity at 60° (left) | Round: 250mm Square: 250mm Rectangular: 250x450mm |

| Cutting capacity at 60° (right) | Round: 250mm Square: 250mm Rectangular: 250x450mm |

| Cutting capacity at 0° bundle – scrapend | Max: 650x450mm Min: 130x20mm Scrap-end: 280mm |

| Cutting capacity at 0° solids (C45) | 280mm (350mm with blade 41mm) |

| Minimum cutting diameter | 10mm |

| Minimum cutting section (on the plate) | 10mm |

| Minimum scrap-end | 265mm (single cut at 90°) |

| Blade size | 5320x34x1.1mm |

| Blade speed | Da 18 a 100 m/min |

| Blade power | 3KW (4KW motor reducer available with blade 41mm) |

| Blade tension | 1900kg/cm2 |

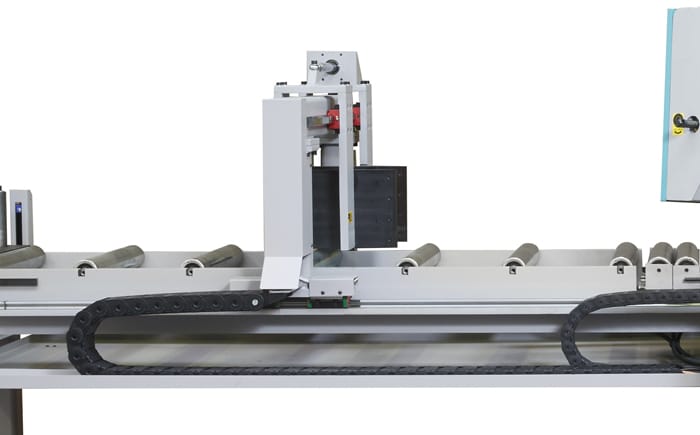

| Feeder length | 2000mm with automatic repetition (available 3000mm length option) |

| Feeder motor power | Brushless BMH 2.5 N-m |

| Hydraulic unit motor power | 0,55Kw |

| Sawframe rotation motor power | 0,55Kw |

| Working table height | 845mm |

| Weight | 4000kg |

| Size | 3930x2870x2300mm |

Reviews

There are no reviews yet.