Imet Ktech 1202 F3000 & 6000

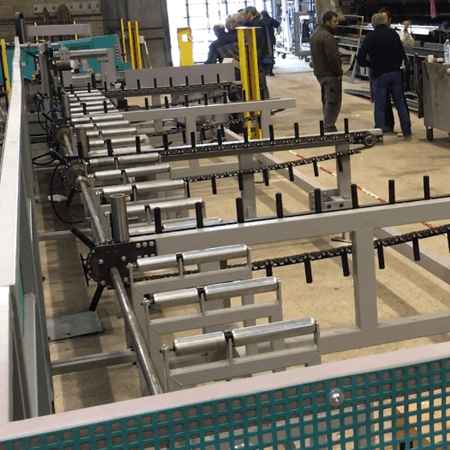

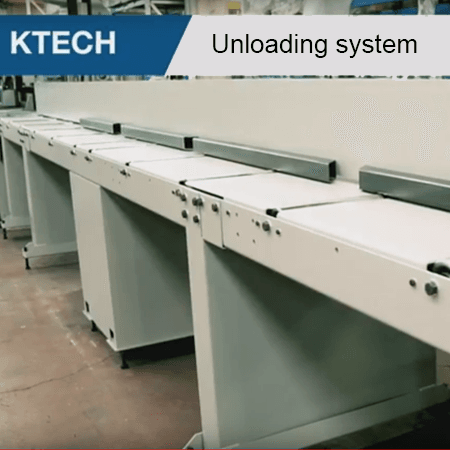

Highly recommended for production cutting of structural sections. The inclined saw blade cuts through square materials more easily, leading to faster cutting times and longer blade life. It also allows for each tooth pitch while reducing stress on the machine parts. These machines come with 3m or 6m incremental feeders. They offer many custom material handling and warehousing solutions. They are the most cost-effective option available. Plus, they are fully supported by our industry-leading 2-year manufacturer’s parts warranty.

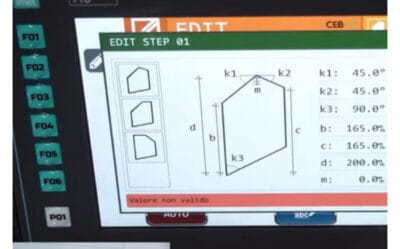

| Cutting capacity at 90° | Round: 680 mm Square: 640 mm Rectangular: 1250 x 600 mm |

| Cutting capacity at 45° (light) | Round: 680 mm Square: 600 mm Rectangular: 870 x 600 mm |

| Cutting capacity at 45° (right) | Round: 680 mm Square: 600 mm Rectangular: 840 x 600 mm |

| Cutting capacity at 60° (left) | Round: 580 mm Square: 530 mm Rectangular: 550 x 450 mm |

| Cutting capacity at 60° (right) | Round: 550 mm Square: 450 mm Rectangular: 550 x 450 mm |

| Cutting capacity with bundle device | Max: 1000 x 350 mm Min: 80 x 80 mm Scrap-end: 400 mm |

| Cutting capacity at 90° (solid C45) | 400 mm |

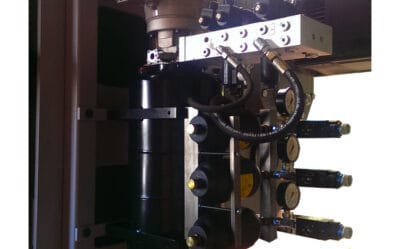

| Blade size | 8140 x 54 x 1.6 mm |

| Blade tension | 3000 kg/cm2 |

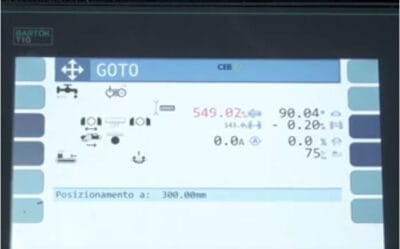

| Blade speed | 18 90 m/min |

| Blade motor power | 7.5 KW |

| Feeder length | 3000 mm with automatic repetition |

| Minimum scrap-end | 400 mm |

| Cutting length | 6 9.999 mm |

| Feeder motor power | Asynchronous with inverter |

| Size – Weight | 5750 x 4200 x 2750 mm (h 850 mm) 4800 kg |

Reviews

There are no reviews yet.