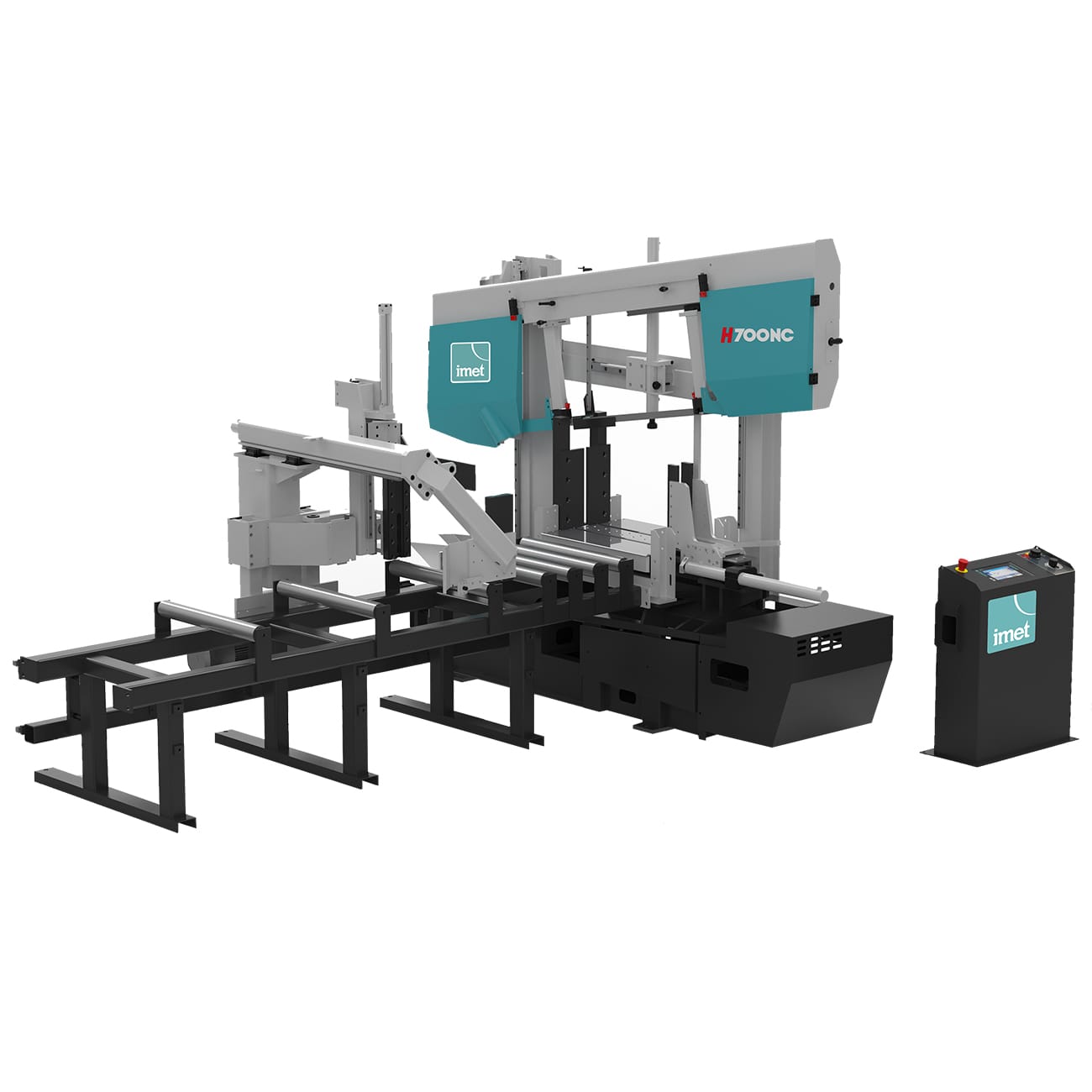

H700 NC F1500-F3000 NC Bandsaw

H 700 NC F1500-F3000 is an automatic double column bandsaw suitable for straight cuts of sectional steels, pipes and solid materials, The machine uses an innovative interface with 10″ touch screen display, guarantees for the highest cutting performance thanks to its rigid structure and 10° inclined blade which reduces stress on machine components, decreases cutting times and extends blade life in square sectional material.

| Cutting capacity at 90° | Round: 520mm Square: 450mm Rectangular: 680x400mm |

| Cutting capacity at 90° full material | 280mm (350mm with 41mm blade) |

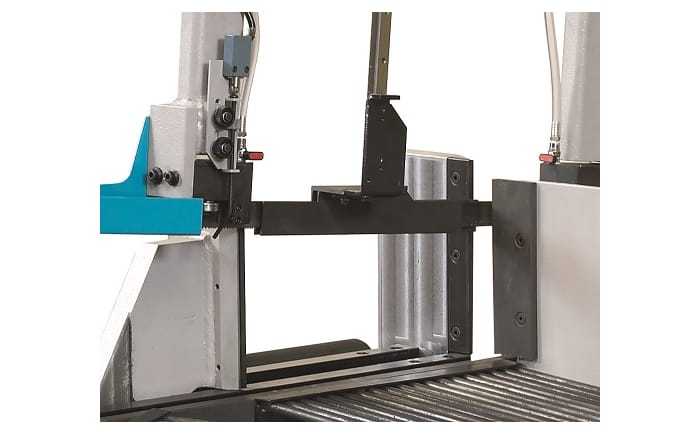

| Bundle cutting capacity | 500x400mm max ; 125x50mm min |

| Blade motor | 3KW (available also 4KW motor reducer) |

| Blade speed | 15-100 m/min |

| Blade size | 5870x34x1.1mm (available blade h 41mm) |

| Blade tension | 2000kg/cm2 |

| Band inclination | 10° |

| weight | 1900kg |

| Size | 1100x3300x2450mm |

| Working table height | 840mm |

| Feeder | 1500mm (option for 3000mm) |

| Minimum scrap-end | 150mm |

| Minimum cutting length | 30mm |

| Feeder motor | 1.5KW |

Reviews

There are no reviews yet.