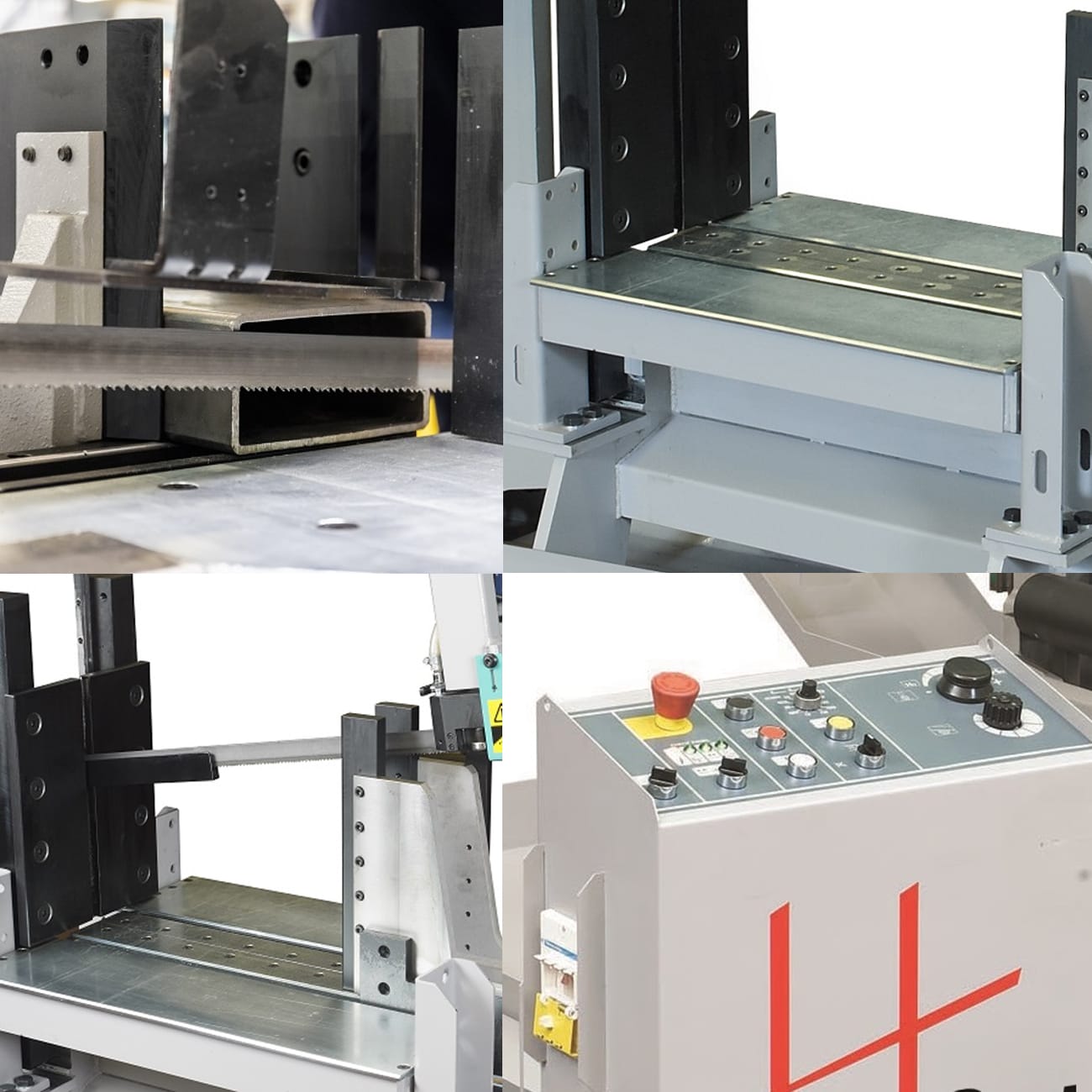

Imet H700 Semi-Automatic Bandsaw

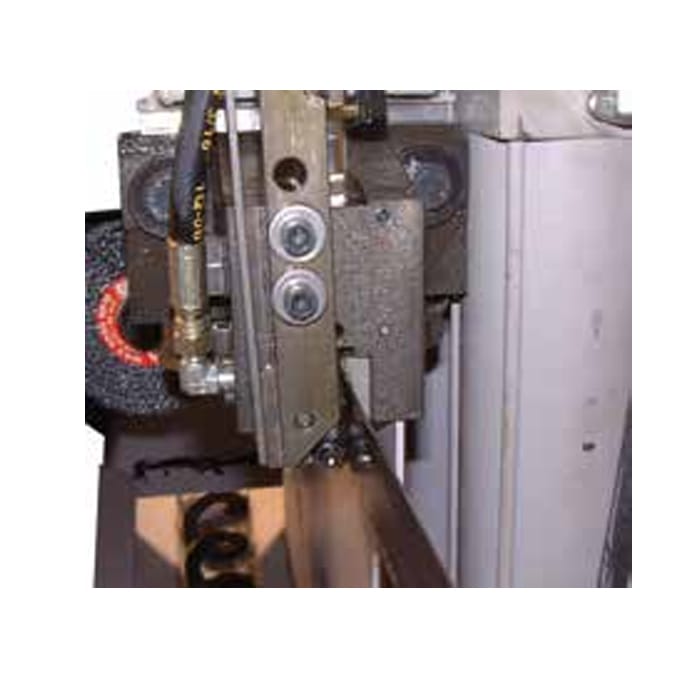

Semi-automatic, hydraulically driven twin column bandsaw for straight cut production work. This saw is built specifically for cutting profiles, pipes, beams and solids and is highly recommended for square section and flat plate as the inclined sawblade feature offers the line of least resistance on these materials. The bandsaw delivers faster cutting times, increased blade life and scope of use for each tooth pitch, with less stress on the machine components.

| Cutting capacity at 90° | Round: 520mm Square: 450mm Rectangular: 680x400mm |

| Cutting capacity at 90° full material | 280mm (350mm with 41mm blade) |

| Bundle cutting capacity | 500x400mm |

| Blade motor | 3KW (available also 4KW motor reducer) |

| Blade speed | 15-100 m/min |

| Blade size | 5870x34x1.1mm (available blade h 41mm) |

| Blade tension | 2000kg/cm2 |

| Band inclination | 10° |

| weight | 1900kg |

| Size | 1100x3300x2450mm |

| Working table height | 840mm |

| Hydraulic unit motor | 0.75KW |

| Hydraulic unit tank capacity | 20l |

Reviews

There are no reviews yet.