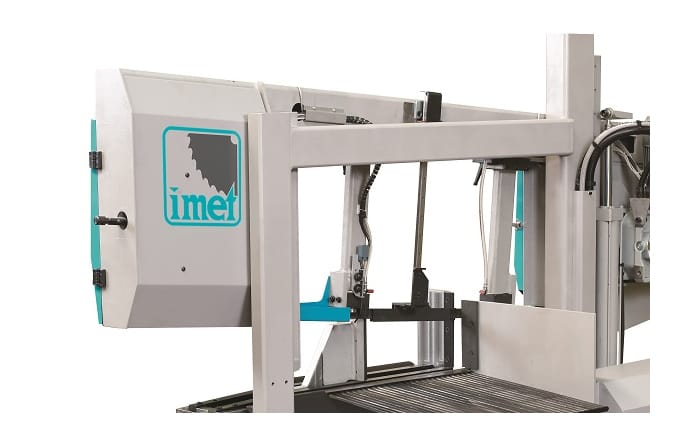

Imet H601 Semi-Automatic Band Saw

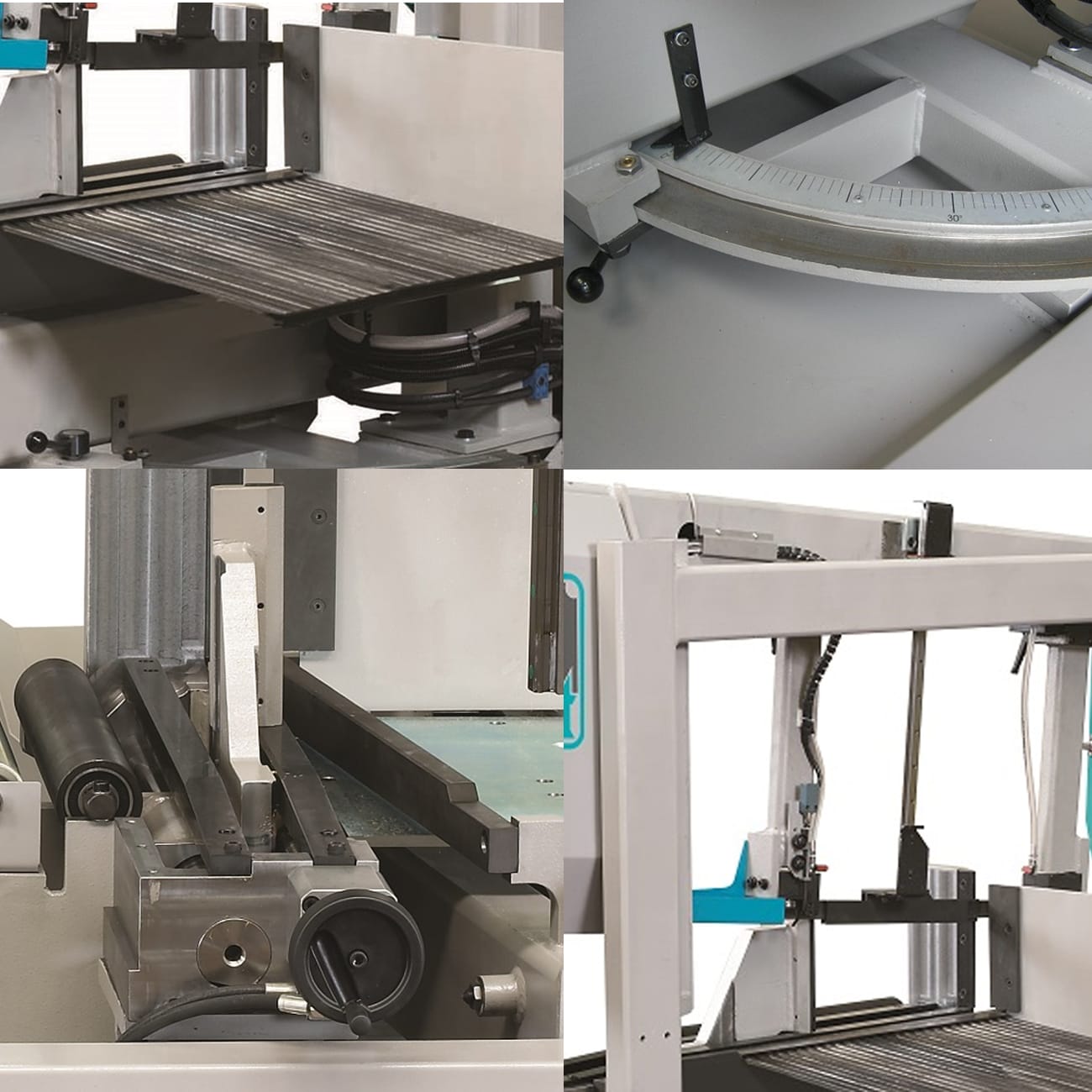

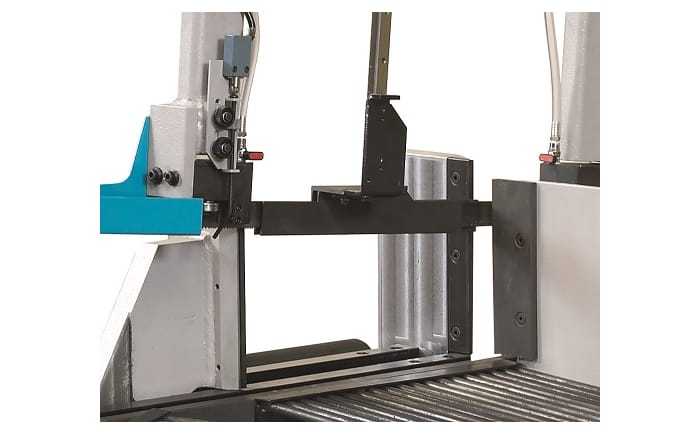

Hydraulically driven twin column, the H601 semi-automatic bandsaw is specially adapted with an inclined sawblade to give maximum performance in square section material, increase sawblade life, reduce cutting times, offer larger scope for each tooth pitch (less blade changes) and significant reduction in load on the machine components.

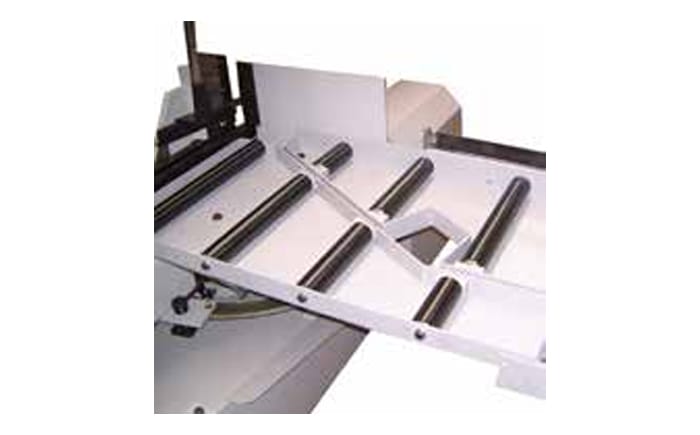

| Cutting capacity at 90° | Round: 510mm Square: 450mm Rectangular: 610x440mm |

| Cutting capacity at 45° | Round: 440mm Square: 440mm Rectangular: 440x450mm |

| Cutting capacity at 60° | Round: 260mm Square: 260mm Rectangular: 250x450mm |

| Cutting capacity at 90° with bundle | Max 600x250mm Min 150x50mm |

| Cutting capacity at 90° solid (C45) | 280mm (350mm with 41mm blade and 4KW motored.) |

| Band Saw Blade size | 5320x34x1.1mm |

| Maximum opening of the vice | 620mm |

| Band Saw Blade inclination | 6° |

| Blade motor | 3Kw |

| Blade speed | 15÷110 |

| Working plate height | 820mm |

| Hydraulic unit tank capacity | 20l |

| Coolant tank capacity | 60l |

| Machine size | 1500x2850x2170mm |

| Weight | 1700kg |

Reviews

There are no reviews yet.