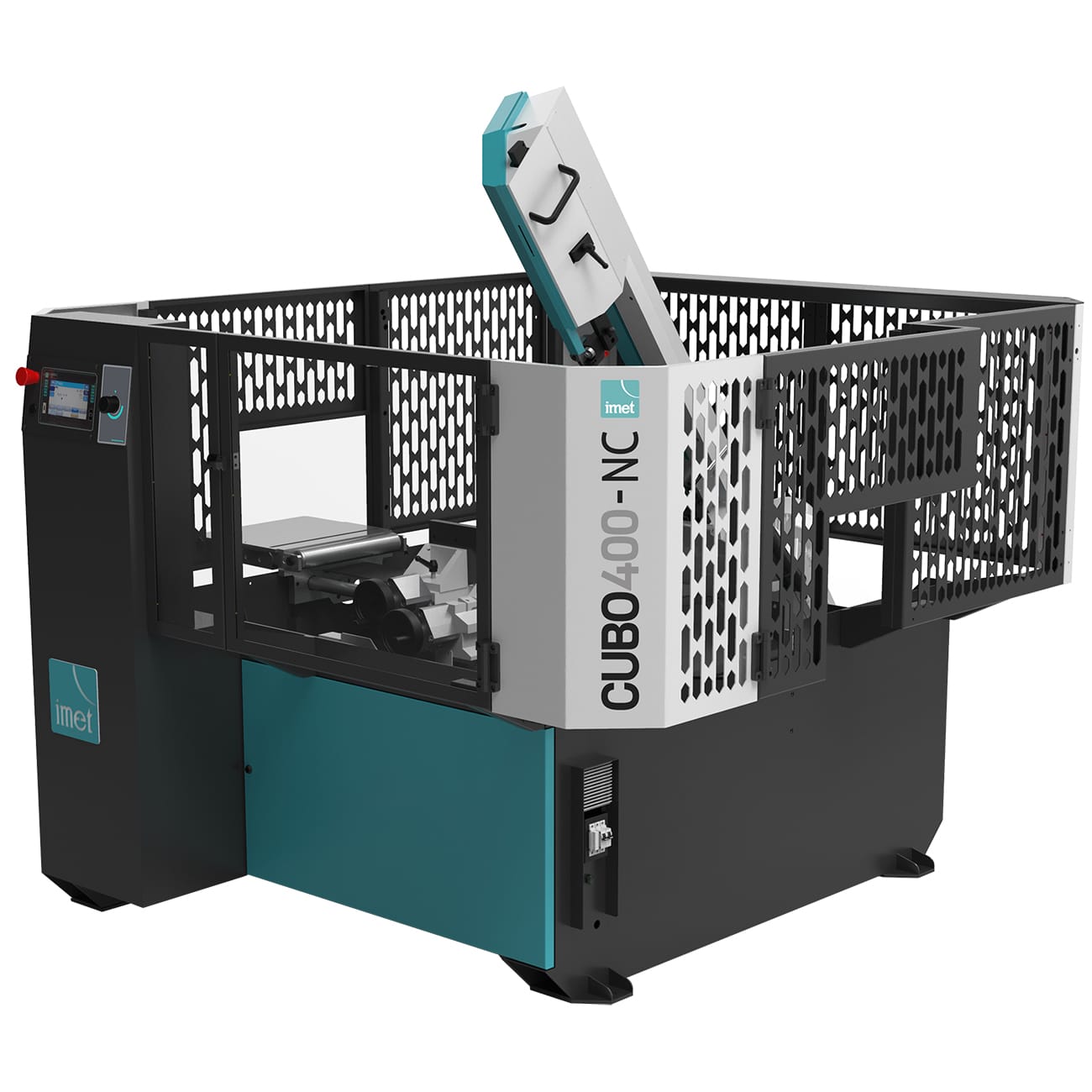

Imet CUBO 400-NC Box bandsaw

Automatic guarded bandsaw with NC control of the cutting parameters one way manual mitre 310mm capacity. Ideal for production cutting situations where large quantities of differing lengths are desired from the same material stock. The Cubo range of automatic bandsaws are recognised for their superior design, build quality and innovative saw guarding features – all proven in production. Delivering consistent performance and reliability which is backed up by an industry leading warranty package.

| Cutting capacity at 0 ° | Round: 310mm |

| Square: 280mm | |

| Rectangle: 400x250mm | |

| Cutting capacity at 45 ° left | Round: 280mm |

| Square: 270mm | |

| Rectangle: 300x200mm | |

| Cutting capacity at 60 ° left | Round: 210mm |

| Square: 200mm | |

| Rectangle: 200x200mm | |

| Capacity with beam cutting device | Max: 300x160mm; Min. 85x10mm |

| Cutting capacity at 0° for full (C45) | 250mm |

| Blade size | 4020x34x1.1mm |

| Blade motor | 2.2KW |

| Blade speed | 18-100m/min |

| Minimum cuttable length in auto. cycle | 15mm |

| Advance carriage stroke | 515mm |

| Advance carriage motor | 0,75KW |

| Minimal waste | 80mm |

| Working area height | 890mm |

| Weight | 990kg |

| Size | 1850x2200x1990mm |

Reviews

There are no reviews yet.