Tronzadoras MG GAA 500-90 CNC

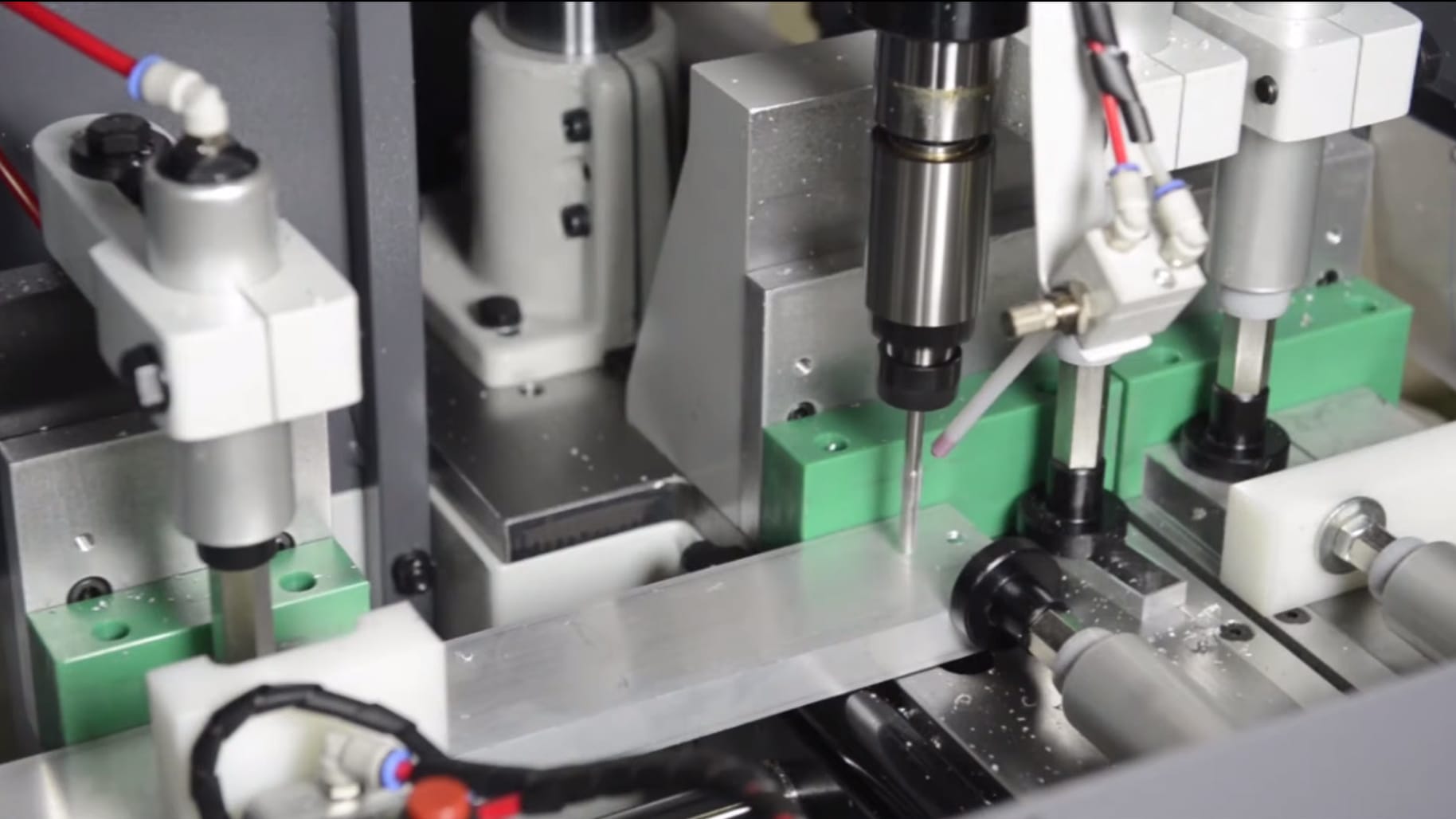

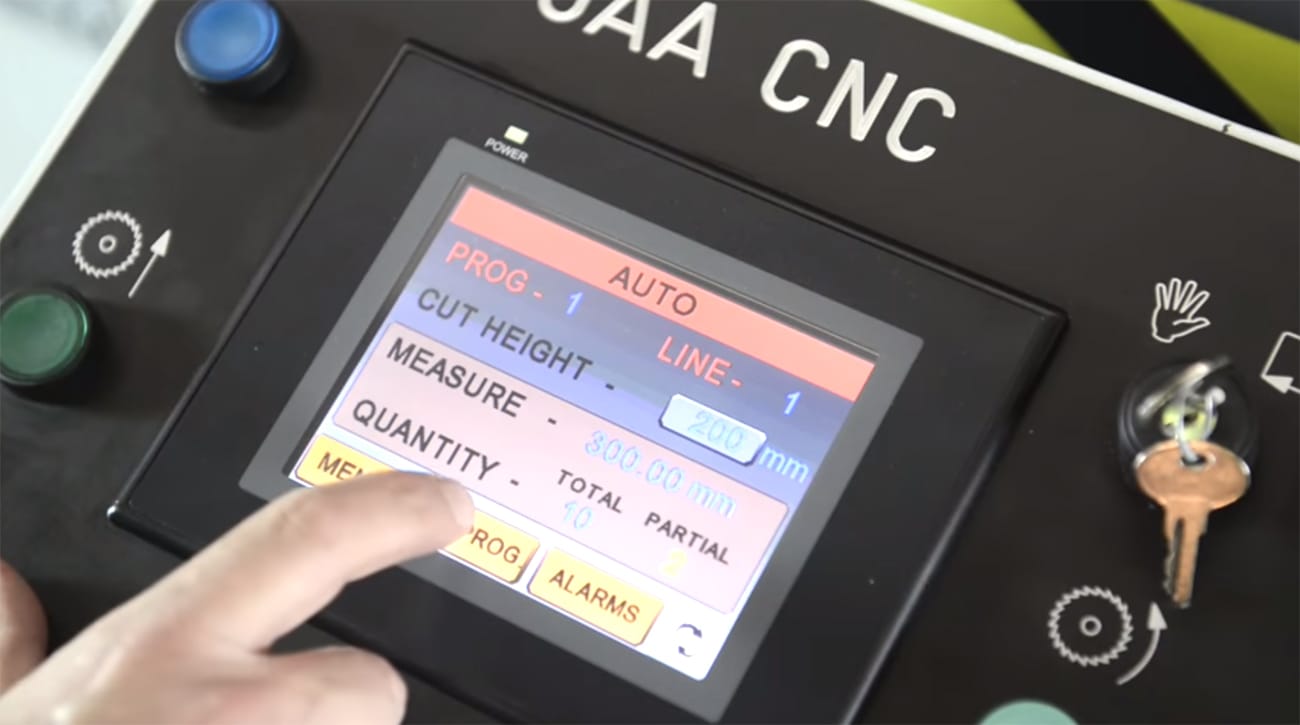

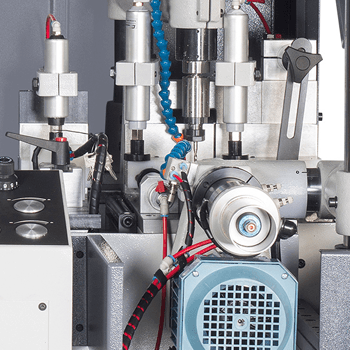

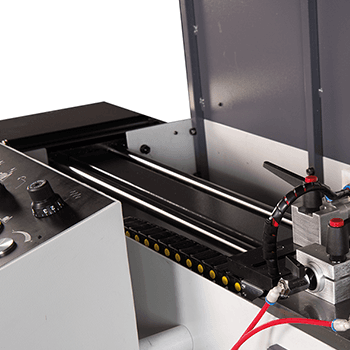

Automatic 90° production sawing of aluminium, copper, brass, plastic extrusions and solids. This cold saw is used in a multitude of industries including, aerospace and aviation, engineering, window and door production, contract cutting, metal stockholders, electronics for heat sink production, lighting, display and exhibition, ventilation and air conditioning, automotive, and many more. The CN servo drive ball screw feeder offers highly accurate and flexible production, and can be configured during production to have vertical and horizontal drilling/punching heads with fixed Y axis position or CN servo Y axis positioning giving a very productive and flexible manufacturing machine. Featuring the very latest 5.6″ colour TFT touch screen technology from Tronzadoras for ease of operator use.

Specification Table:

| Technical | GAA-500-90 CNC | |

| Capacity 90° | Round | 150 mm |

| Square | 150 x 150 mm | |

| Rectangle | 250 x 75 mm | |

| Motor | 4,0 HP | |

| Blade Diameter | Ø 500 mm | |

| Blade Speed | 3000 RPM | |

| Blade Axis Diameter | 50 mm | |

| Maximum Cutting Height | 150 mm | |

| Feeder Advance Range | 700 mm (Multiple Advance) | |

| Pneumatic Clamps | 6 (3 Horiz + 3 Vert) | |

| Weight | 470 kg | |

| Dimensions | 2050 x 1150 x 990 mm | |

Cutting Chart:

Reviews

There are no reviews yet.