Everising vice pressure reducer

Kit to add universal vice pressure reduction function, one single valve and gauge situated on the main control panel reduces pressure to the main and shuttle vice for cutting thin wall sections and tubes, the kit includes a gauge to accurately set and record pressure to be repeated.

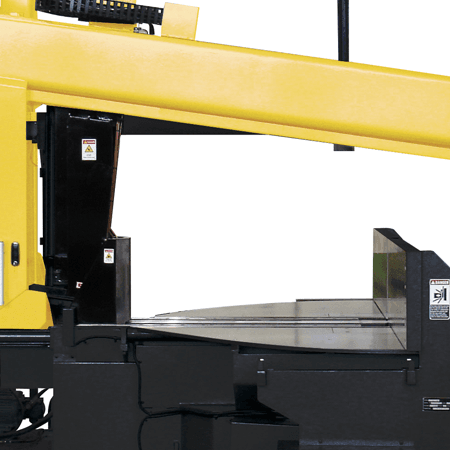

Dead roller table

Options for 2M and 3M long

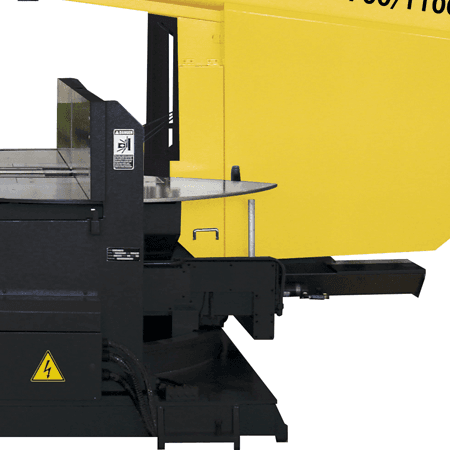

Power feeding roller table

3 M long

Hydraulic work lift roller

Manual feeding – outfeed side

Reviews

There are no reviews yet.