Everising H 260 HB-NC Horizontal Bandsaw

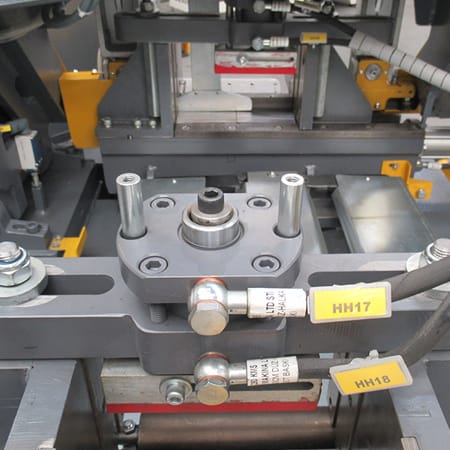

The Everising H-260 HB-NC Band Saw is an industrial-grade, automatic horizontal band saw designed for precise and efficient metal cutting, particularly for medium-sized to large workpieces. With a solid, robust frame and advanced NC (Numerical Control) capabilities, this saw is commonly used in manufacturing, metalworking, and fabrication environments that demand high productivity and repeatable accuracy.

Features:

- Cutting Capacity: The H-260 HB-NC can typically handle work pieces up to a maximum cutting diameter of approximately 260 mm (10.2 inches) for round materials, and similar sizes for square and rectangular stock. This makes it versatile enough for various mid-size material dimensions.

- Automatic Feeding System: Equipped with a programmable NC system, the band saw allows users to automate feed length, cutting cycles, and material indexing for consistent results. This system is ideal for high-production environments where manual adjustments would reduce efficiency.

- Precision and Control: The NC controller features an intuitive display, where operators can input specific cutting parameters, feed rates, and even batch cutting specifications. These controls enhance precision while also offering flexibility for different job requirements.

- Blade and Speed Options: The H-260 HB-NC supports adjustable blade speeds and feeds, making it adaptable for different metals and cutting conditions. The variable blade speed feature is particularly useful for cutting harder metals or adjusting for different thicknesses and densities.

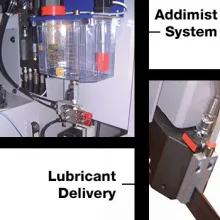

- Cooling System: Equipped with a powerful coolant system, it helps to maintain blade temperature and reduce wear during cutting. This cooling function improves the machine’s longevity and ensures smooth finishes on cut surfaces.

- Durable Construction: Built with a heavy-duty cast iron frame, this bandsaw is designed to minimize vibrations and provide stability during operation, which improves cut quality and extends the life of both the machine and the blade.

- Safety Features: The band saw includes essential safety mechanisms such as automatic shutdown at the end of each cycle, blade breakage detection, and emergency stop buttons. These features help ensure operator safety and prevent equipment damage.

The Everising H-260 HB-NC horizontal bandsaw is suitable for cutting various materials, including steel, aluminum, and other metals. Its combination of automation, accuracy, and sturdy design makes it a popular option. It is widely used in industries such as automotive, aerospace, and heavy machinery.

Specification:

| H-260 HB-NC | |

| Capacity – Round | 260 mm |

| Capacity – Square | 310 x 260 mm min. clamp width 285 mm |

| Bundle Cutting – Width | 145 to 190 mm |

| Bundle Cutting – Height | 30 to 130 mm |

| Blade Speed | 20 to 100 m/min (65 to 330 fpm) (INVERTER) |

| Blade Drive Motor | 3.7 kW (5hp) |

| Hydraulic Pump Motor | 0.75 kW (1hp) |

| Coolant Pump Motor | 0.1 kW (1/8hp) |

| Blade Size | 3920 x 34 x 1.1 mm |

| Blade Tension | Hydraulic |

| Index Length | 400 mm / 400 mm x 9 times |

| Machine Weight | 1750 kg kg |

| Floor Space (l x W) | 2170 x 2100 mm |

Reviews

There are no reviews yet.