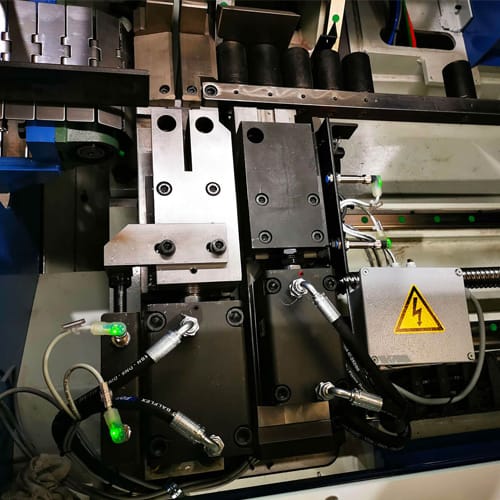

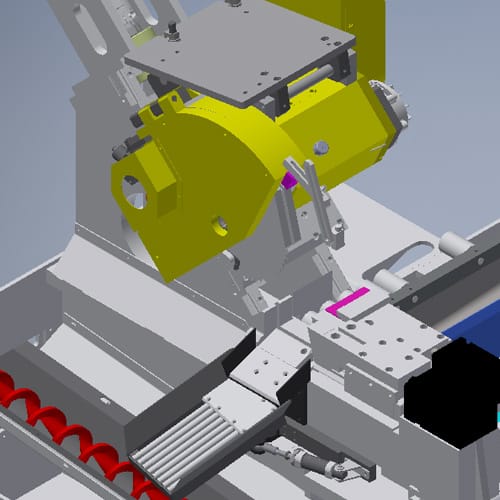

DM 3000A In line De-Burring

Machine features

- Manual setup of deburring type using the two handwheels

- Automatic position of moving head, based on current cutting length data

- Workpiece feeding gripper mounted on travelling carriage to prevent material scratching

- Wear-proof transfer teeth with optional plastic coating to prevent material damage

- Brush motor 7.5 Kw

- Manual lubrication of sliding elements

- Possible speed adjustment of deburring machine chains

- Chip blow-off (option)

- Deburred workpiece storage unit (option)

- Supply of dedicated brushes for stainless steel material cutting

EW-3 Extractor

Complete swarf extraction system taking from both sawblade chambers, fully compliant to handle aluminium, pvc, brass, wood, copper and composite materials. The steel container is removable for easy emptying, and the filter bags are maintained with either the standard manual shake lever or the optional pneumatic shake.

Addimist

Pure oil micro-mist blade lubrication system recommended over the standard soluble system, as it delivers a high performance neat oil in minute highly controlled doses. Giving a cleaner working environment with no odours or risk of skin irritation sometimes connected with soluble fluids. Each dose cane be scaled by adjusting the size of each pulse and the frequency of each pulse.

Reviews

There are no reviews yet.