- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

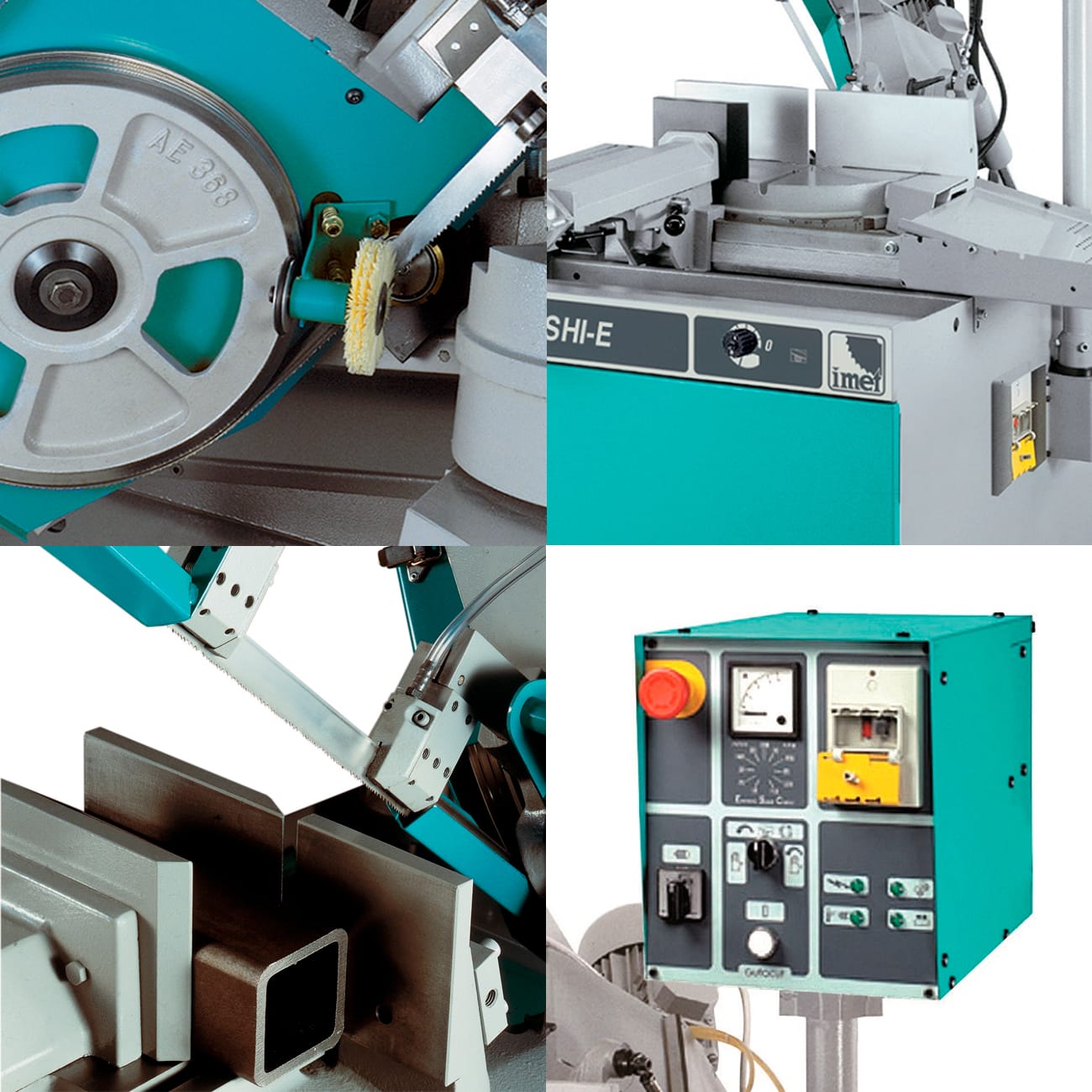

The ultimate workhorse in smaller metal cutting bandsaws. The BS400 autocut bandsaw is noted for extreme performance and reliability and comes with a rotating cutting table and mitre cutting from 0° to 60° left and from 0° to 45° right. Positive stops at 0°, 45°, 60°. Ideal and highly recommended for the demanding workshop and production situations.

The unique below-centre pivot means the bandsaw blade is inclined at the end of cut for optimum performance and blade life on square sections and flat plate materials. This specialist feature reduces stress and load on the machine components.