Custom Builds BS 350/60 AF-NC Band Saw + Drilling Unit

The combination of unparalleled expertise through 4 group companies together with innovative conception and the deployment of quality components deliver amazing solution results. This example of a band saw + drilling unit illustrates one of many projects where complete production cell was required.

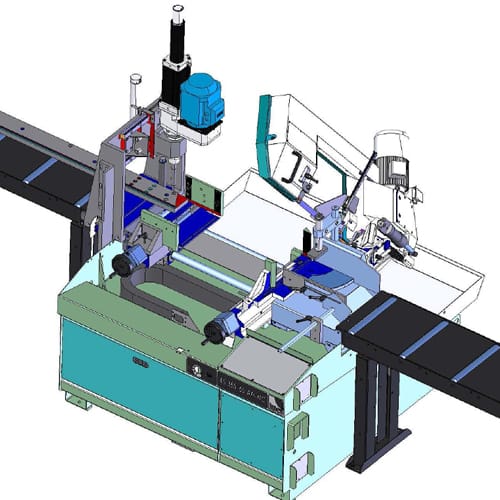

Automatic Band Saw + Drilling Unit Design

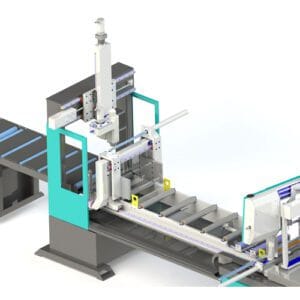

This is an integrated cutting system with BS 350/60 AF-NC customization, automatic bar feeding and drilling and CNC management of the working cycle with 10″ touch screen display.

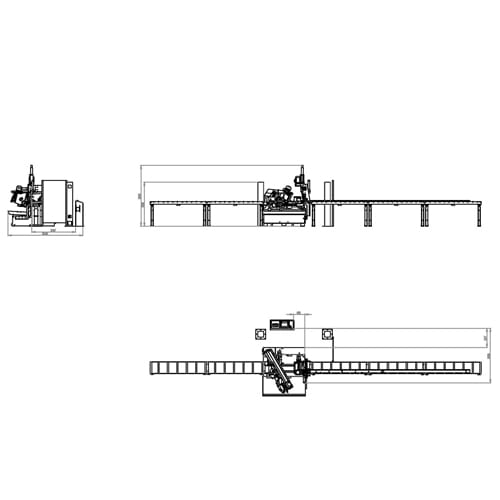

Boasting an integrated working cycle for drilling and cutting of bars with synchronized movement between material feeding, drilling and cutting. The system is composed of 4m free rolling roller table on the loading side, 500mm single stroke feeder carriage and 6m free roller table for unloading.

The drilling device has a mechanical stop with double axis, and the customer can change the drill tip with countersinking tip. Once positioned the bar on the roller table, the feeder vice locks it, positioning it in the drilling station, so after being processed according to the set program, the bar advances for the cutting process. Program settings and cutting process are managed by machine CNC with customized 10″ touch screen display (T10 model like Ktech’s) on a mobile console.

Find out more about Imet’s customised solutions here: IMET | Customized Solutions (imetsaws.com)

Reviews

There are no reviews yet.