- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

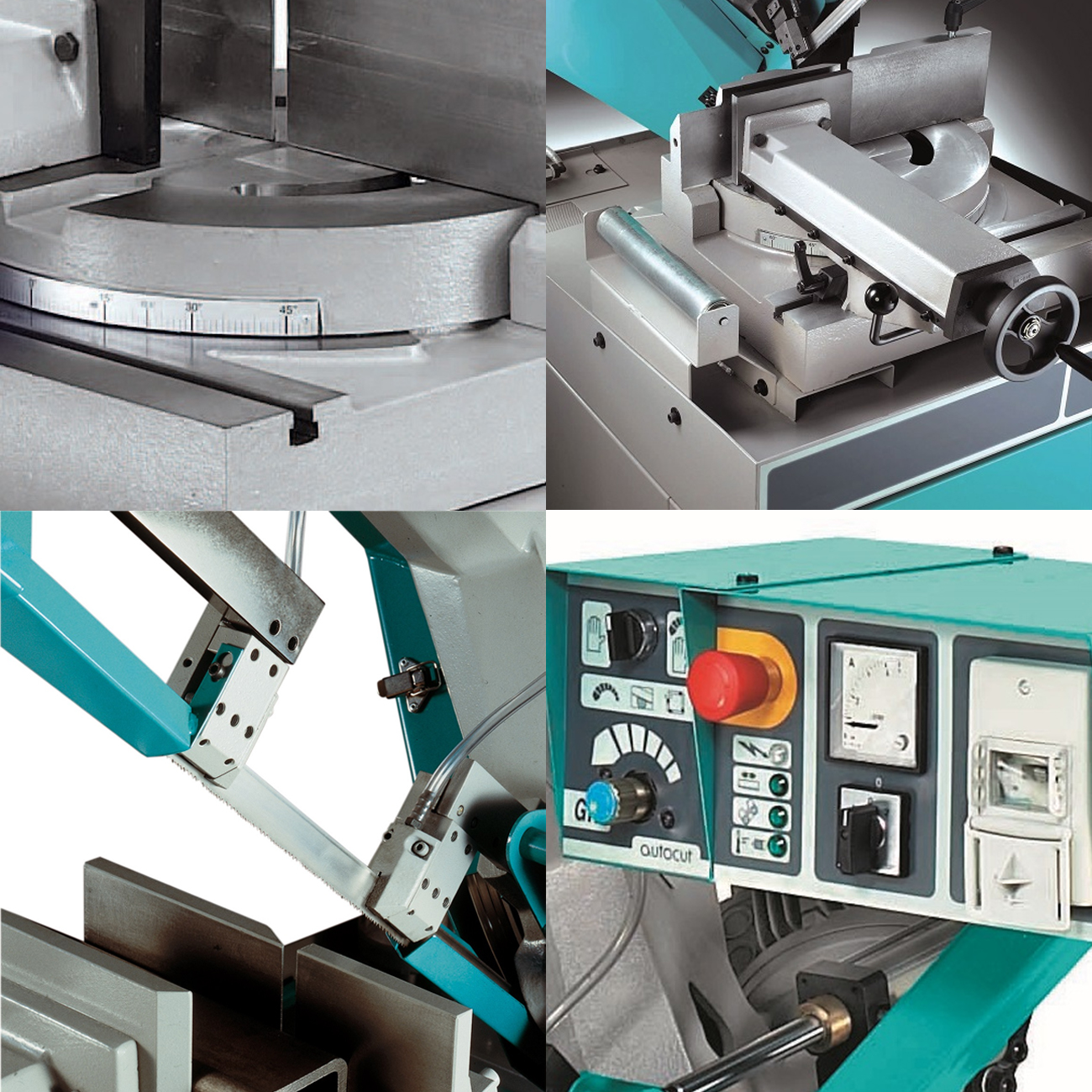

A very dependable, well proven and versatile autocut band saw machine for Ferrous materials like Steel – the mainstay of many a busy workshop. Ideal for general workshop and medium batch production of sectional and solid materials. Mitre cuts to 45° left and 60° right with positive mitre locations at 0°- 45°- 60° left & 0° – 45° right.

This two way mitre swing head and rotating cutting table is ideal for general fabrication and manufacturing applications, especially where opposed mitre cuts are required.

A tough, well designed machine offering very flexible and precise capabilities together with an industry leading 24 months parts warranty.